[3D Printing Application] BCN Transforms Production Line: Doubles Delivery Time and Saves 260,000 Yuan in Costs!

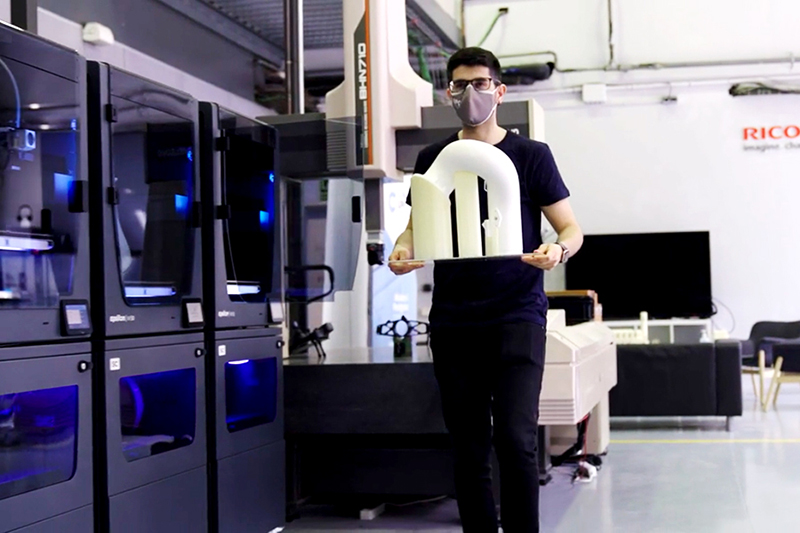

The technical team "UPC CIM" at the Polytechnic University of Spain uses the IDEX (Independent Dual Extruders) 3D printer to help many SMEs and startups produce various industrial parts, ranging from automotive and pharmaceutical equipment to railway ventilation components. From prototyping and industrial parts to auxiliary tools and complete production lines, they have successfully reduced production costs and delivery times while maintaining functionality and quality. See three examples of 3D printed industrial parts:

The CIM UPC manufacturing plant has a very large production capacity. In 3D printing technology , the team specifically chose the BCN3D 3D printer , which has the unique IDEX (Independent dual extruders) technology. The two printhead systems are completely separate and can move independently. During operation, the movement of the nozzles will not interfere with each other, and a small production run can be completed on average every two days!

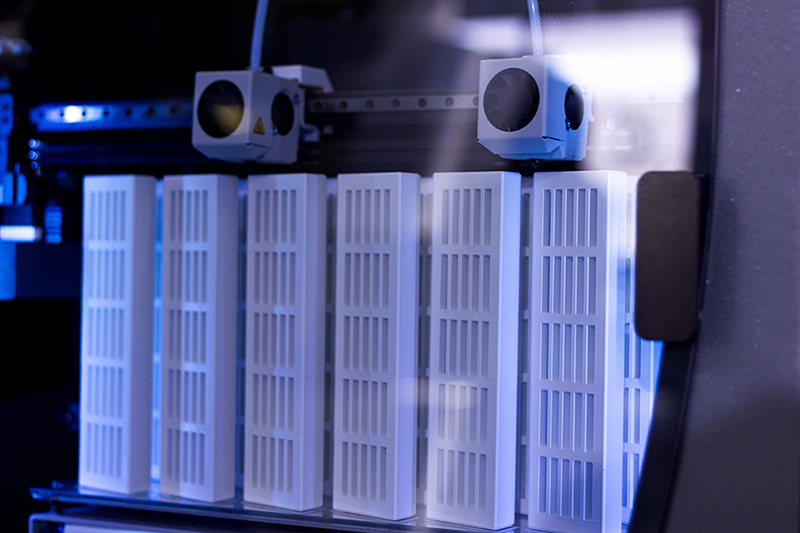

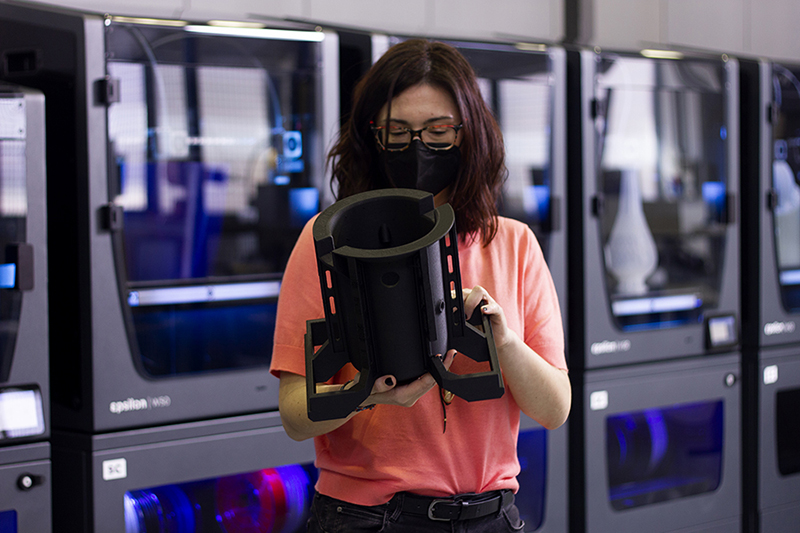

Ventilation Grill

Common "ventilation grilles" are made through injection molding, which requires designing a basic model first, and then mass production through molds and injection molding equipment, taking at least a year to complete. The CIM UPC team first 3D scanned the parts, and then used 50 BCN3D printers to produce them at full capacity. Thanks to the independent dual extruders (IDEX) technology, which mainly uses "copy" mode for printing, they successfully completed the production of all items within six months, saving half of the delivery time!

When using IDEX technology for 3D printing , you can choose between "copy" and "mirror" modes. The two printheads will work simultaneously, achieving double the efficiency and productivity in the same amount of time!

• Car intake manifold

The CIM UPC team used 3D printing technology to design automotive part samples. The internal details of the intake manifold are complex, and to ensure accuracy and quality, the stability of the 3D printer and the materials are very important. Using the BCN3D printer with the SC Smart Cabinet , the humidity of 8 rolls of 3D printing filament can be controlled at one time. The uninterrupted power supply system can also effectively prevent any power outages during operation, so that each 3D printing operation can be carried out smoothly even if no one is there to monitor it at all times.

The BCN3D Smart Cabinet SC keeps each roll of 3D printing cable in optimal condition, simplifying the 3D printing process. Users can more easily control the operation and obtain high-quality 3D printed products.

Pharmaceutical pure water equipment parts (Watertight Tank)

For a particular project, the large-scale production equipment used in the pharmaceutical industry required the creation of 15 sample models. CIM UPC evaluated various manufacturing technologies and conducted cost analysis. Ultimately, they chose to use hot melt stacking (FDM) technology , combined with PP (polypropylene) , a common industrial material, to produce the models. This saved nearly NT$260,000 in costs, making it the most economical and efficient option for the company!

The CIM UPC team has successfully helped various companies transform their production lines through 3D printing technology, addressing issues related to time cost, technical materials, and mechanical performance. Their goal is to extend 3D printing technology to more industries, improve global industrial operations, and comprehensively upgrade corporate efficiency. Did you enjoy this sharing? We offer more than just 3D printing ; contact us now to learn more about the BCN3D series 3D printers .

Follow our fan page to stay updated on the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References

Follow our fan page to stay updated on the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References