[3D Printing Applications] The secrets to winning a racing championship? 3D printing processes are more flexible!

How to use 3D printed parts in engines? 3D printing technology is commonly used in sample making and design development, while in fields such as automotive parts and factory machinery, racing is one of the fastest and most technologically advanced sports in the world!

Hartley Engines and Motorsport is a company that designs, develops, and manufactures high-end engines and parts for motorsport and small car companies. Their clients have won numerous championships in motorsport and have received many awards for innovation in motorsport engineering. In the past, much of their development work was highly confidential and only available to select clients. Recently, they have expanded their business to include engine kits for other engine developers and have begun directly retailing more parts to consumers around the world.

"We realized we couldn't build engines for everyone because there simply wasn't enough time," said Nelson Hartley, owner of Hartley Engines. "But we discovered that by providing the parts we manufacture, we could serve more people better." One of their strengths is their ability to design and develop products and prepare them for production very quickly. The introduction of 3D printing equipment to produce parts has also taken their manufacturing process to a new level.

Nielsen (right) discusses design concepts at a seminar.

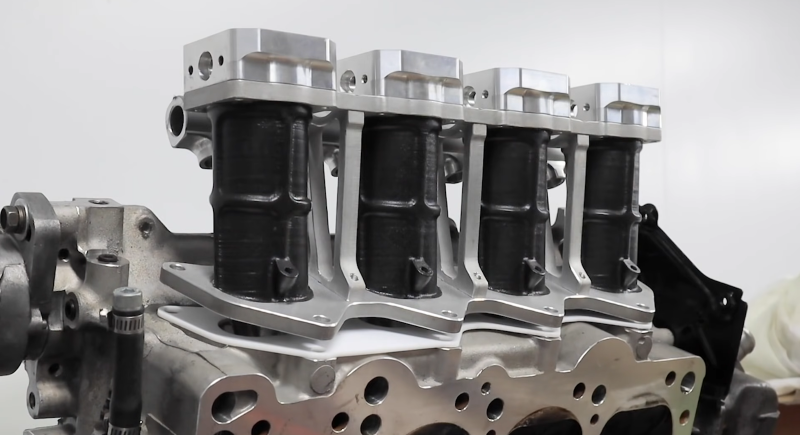

Nielsen and his team have been researching "how to use 3D-printed parts in engines" for years. After introducing new 3D printing equipment, they redesigned the aluminum parts used for the intake throttle body. "The advantage of 3D printing is the flexibility in design. We place great importance on the intake shape; through 3D printing, we can create extremely complex curves and shapes that match the model."

3D printers cannot replace CNC machines, but similarly, anyone who says production work cannot be done on 3D printers is wrong. As business grows, new methods are needed to address the challenges of production and R&D speed. "The cost of 3D printers is very low, about 1/30th the cost of our 5-axis CNC machines, and the parts we manufacture on them are just as valuable to consumers… Therefore, even though the production speed is slower, running multiple 3D printers simultaneously is, in some cases, more efficient than CNC machines, resulting in a very high return on investment!"

"In the past, we often spent a lot of time designing and building our machines to process or manufacture a part. Now, with a 3D printer , you only need to press the start button, and no other tools are required."

Racing engine using hybrid 3D printed parts

3D printing is also used to manufacture turbocharger chambers for turbine engines. The parts printed using 3D printers are of exceptionally high quality and boast surprisingly good performance! Nielsen said, "We had spent 3-4 years developing this before, but since using INTAMSYS FUNMAT HT , we've solved 99% of the problems we encountered. The quality of the parts is amazing, and we've already started production!"

Larger sizes can now be manufactured, with more connection space and faster production speeds. In the future, this new manufacturing method will also be used to design numerous air intakes and engines. Did you enjoy this sharing? Learn more about 3D printers now, follow 3Dprinter regularly, and receive the latest application examples! Contact us now to answer any 3D printing questions you may have.

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/