[3D Printing Applications] Snapmaker Single Printhead, Dual Printhead, IDEX Independent Dual Printhead: Advantages and Disadvantages and Comparison

Most printers have only one printhead, while some have two. So, which is better, a single printhead or a dual printhead? If you have the budget, in most cases, two printheads are better than one. In fact, dual printhead 3D printers have become increasingly common in recent years, even showing a trend of replacing single printhead printers.

Why are dual-head 3D printers becoming a trend?

Two-color or mixed-material printing

Dual printheads allow the use of two different colors or types of filaments on the same printhead, enabling the printing of more complex and colorful objects.

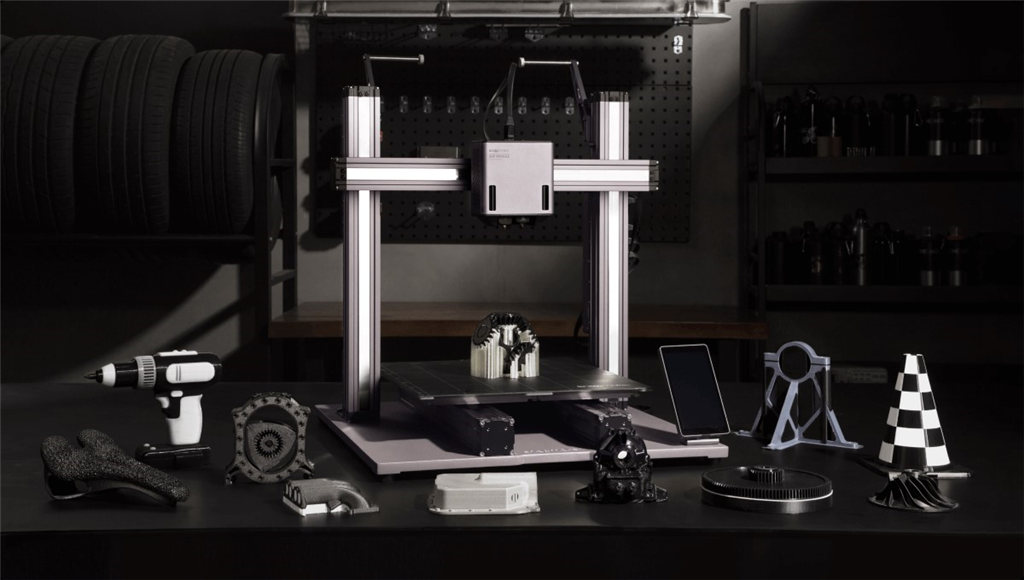

Snapmaker Dual Printhead 3D Printing Module Installed on Snapmaker 2.0

Two-color printing is not uncommon. Even with a single printhead, a similar effect can be achieved by manually changing the filament. However, if you want to use two different materials on the same object, such as printing a flexible/rigid composite object using ABS and TPU, manually changing the filament can be very cumbersome, and the different optimal settings for the two materials can easily lead to printing failures. Rather than taking the risk and going through the trouble, it's better to print them separately and then glue them together.

In contrast, when using a dual-head printer, different parameters can be set directly in the slicer software for each printhead, allowing dual-material printing to be completed in a single printing job.

Separate support or PVA support combination

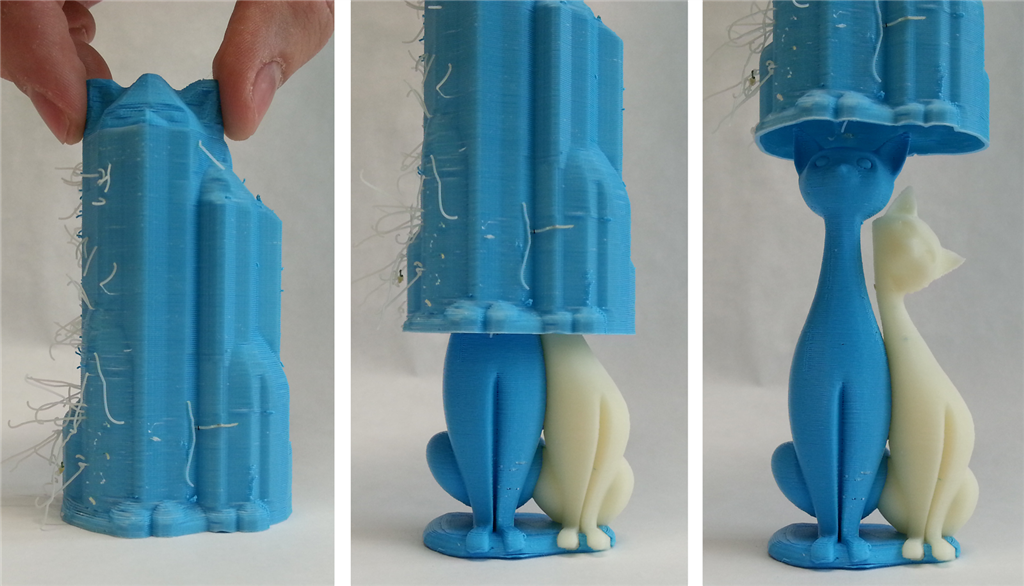

The formulation of peelable support materials has lower interlayer adhesion and mechanical brittleness, so they can be peeled off with very little force. The ability to easily print removable (or " breakaway ") supports is perhaps the main reason most people buy dual-head 3D printers. If time is limited, breakaway supports are easier to remove than PVA supports, maintaining dimensional accuracy of printed objects and providing a high-quality surface finish.

Separable support material

Soluble materials are soluble in water or other solvents. The most commonly used is PVA (polyvinyl alcohol) . It is very sensitive to moisture and decomposes upon contact with water. Utilizing this property, it can be used as a support material to fill in hard-to-reach geometries, allowing liquid to flow into them. After printing, immersing the printed material in water causes the support material to dissolve, leaving a smooth printed surface.

Some additional features

Dual printheads also enable additional functions, such as a backup mode. In single-printhead printing, if a printhead malfunctions or becomes clogged, or runs out of cable, the other idle printhead can take over and complete the remaining printing. This improves overall uptime and reliability.

It performs well in slicing software applications.

Building a dual-nozzle system by copying parts is mechanically simple, but the real challenge lies in the software. The widespread adoption of dual nozzles is inextricably linked to improvements in slicing software. Slicing algorithms are better at planning optimal toolpaths for dual nozzles to minimize movement and retraction. They also better allocate the different model parts to be printed by each nozzle to maximize utilization and minimize idle nozzles. These software advancements have made dual nozzles more user-friendly and reliable, leading to their wider adoption.

Disadvantages of dual nozzles

With the development of the 3D printing industry, desktop printers are now more economical and easier to use. Dual printheads have also become a common feature in many budget products, allowing more users to experience the benefits of dual printing. However, dual printheads also have some drawbacks:

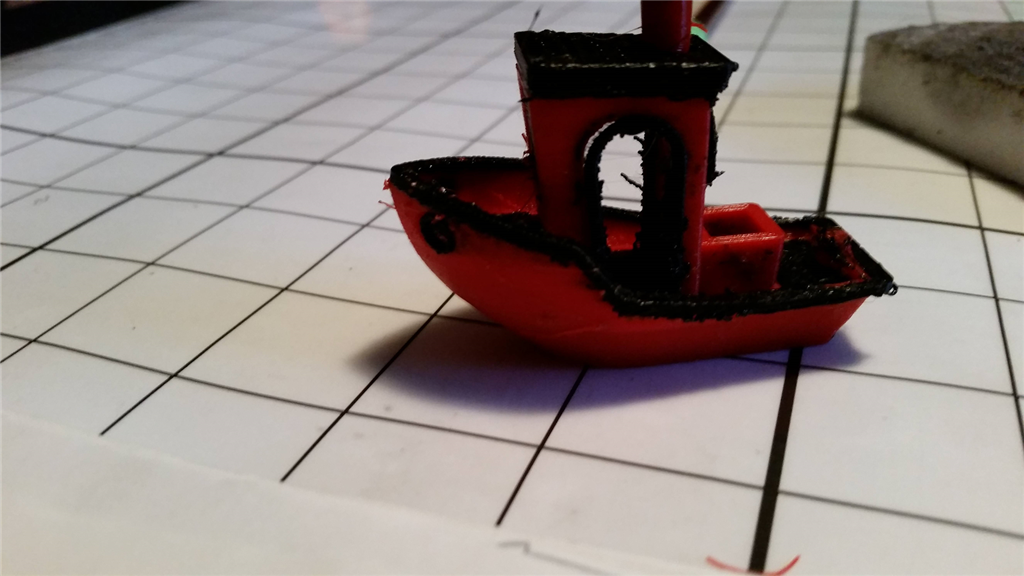

Source: Simplify3d

• Cross-contamination and collision: In two-color printing, idle printheads may leak material due to residual heat, causing contamination as they slide across the printed parts. If the nozzle is too low, it may even collide with the printed parts.

• More maintenance: Twice the number of hot ends means twice as many parts that need to be inspected, cleaned, and replaced in case of paper jams or blockages.

• Relatively smaller build volume : Because the printhead itself occupies a certain length along the X-axis, the build volume of a dual-printhead printer is smaller than that of a single-printhead printer, assuming the printer frame size is the same. This is especially noticeable when upgrading from a single printhead to a dual printhead.

The drawbacks of maintenance and build-up may be unavoidable, but cross-contamination and collisions can be addressed. The most common approach is to incorporate retraction in the slicer , temporarily twisting the filaments in the nozzle during movement to prevent leakage.

Another approach is to use a main tower —printing another object simultaneously with the main print job—providing a place for inactive nozzles to remove material from oozing or leaking, rather than on the print job itself. Similar solutions include oozing shields, which surround the print job and wipe away oozing material as the nozzles approach it.

Leak-proof cover (Source: IceSL)

Some printers also have a wiping device installed directly on the machine, at the same height as the nozzle, so that any residue can be wiped away as the nozzle passes through the device. Simple and practical.

Snapmaker J1s nozzle wiping device

However, this doesn't solve the collision problem, and material towers/anti-fog hoods increase time and material usage. In contrast, mechanically raising inactive nozzles seems more versatile. For example, the Snapmaker dual-nozzle module uses a motor to automatically raise/lower the nozzles, avoiding contamination/collisions and enabling quick and quiet nozzle switching.

Automatic nozzle lifting device for Snapmaker dual-nozzle module

Finally, there is an ultimate solution – the IDEX (Independent Dual-Head) 3D printer . As the name suggests, the two printheads can move independently. When printing with one printhead, the other can remain stationary in a corner without heating. When both printheads are active, they can print independently without interfering with each other. However, to further reduce the impact of exudate, the IDEX printer can still use wiping devices, retraction devices, and packing towers during dual-head printing.

Independent and Dependent Dual Nozzle Systems

Compared to ordinary dual-nozzle modules, IDEX has some advantages, but it also presents some challenges for manufacturers and users.

Snapmaker J1 printing in copy mode

advantage

• Minimal contamination and impact: In dual-head printing, the idle printhead remains in a corner instead of moving with the active printhead. Before the next printing job, any oozing material can be wiped away using a wiping device or filler tower. Therefore, IDEX effectively eliminates oozing contamination and impact problems.

• Mirror and copy printing: IDEX printing presses can print two mirror images or identical objects simultaneously, doubling productivity. This is extremely useful for the mass production of small items such as chess pieces.

• Lighter weight, higher precision: Compared to mechanically connected dual printheads, the single printhead of the IDEX printer is lighter, moves faster, has less floating mass, and is more precise.

shortcoming

• Greater manufacturing difficulty: Precise alignment of the individual nozzle frame and nozzle requires strict manufacturing and assembly tolerances.

• More Difficult Calibration: Calibration is one of the biggest challenges in the design of IDEX printers. The two independent printheads not only need to be calibrated with the bed, but also with each other on the X, Y, and Z axes. Poor calibration can lead to cracks or even print breakage due to poor layer adhesion.

• Higher Cost: IDEX printers not only have higher software development costs, but also require independent or semi-independent motion systems in terms of hardware, including motors and supports for each printhead. If they don't share an X-axis, additional linear guides, lead screws, or belts are also needed. These factors mean that IDEX printers are generally more expensive than ordinary dual-head printers.

How to choose between single-nozzle, dual-nozzle modules, and IDEX independent dual-nozzle systems .

Here are some things to consider when making a choice:

Single nozzle

• The simplest and most economical choice

• Easier to calibrate and maintain

• Limited to printing in a single color/material

Dual nozzle module

• It can perform two-color or two-material printing without generating a large amount of filament waste.

• Allows for dissolvable and detachable supports

• Cost is higher than that of a single nozzle

• Potential collision risks and idle leakage issues

• Calibration is relatively troublesome

IDEX Independent Dual Spray Head

• Printing identical or mirror images is twice as fast

• Two-color or material printing, with minimal waste of filaments.

• Allows for dissolvable and detachable supports

• Minimal risk of collision or leakage

• Highest cost, requires calibration

Generally, a single printhead is sufficient for most amateur printing. If you need to do two-color printing or have easier support removal, you should consider a dual-printhead system. For advanced applications or speed, if your budget allows, the IDEX system may be the ideal choice. Hopefully, you find the printing method of your dreams!

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook: https://www.facebook.com/3dmart.com.hk/

Instagram: https://www.instagram.com/3dmart

LinkedIn: https://www.linkedin.com/company/3dmart/

References