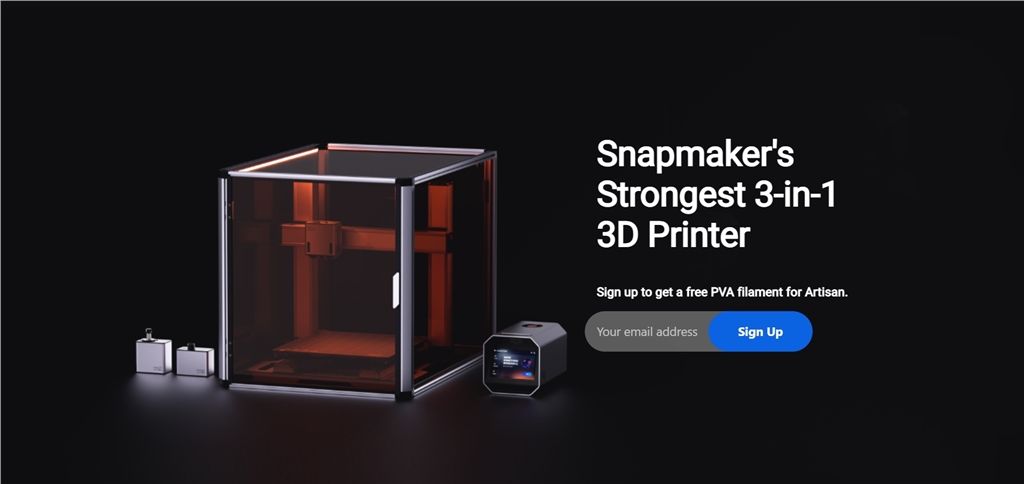

[3D Printing News] Snapmaker Artisan 3-in-1 Features Explained! A Major Release!

Following Snapmaker 2.0 , the Snapmaker R&D team spent 516 days creating a brand-new product that pushes the limits of 3-in-1 3D printers, naming it Artisan . It can meet the needs of different creative scenarios, truly turning your home into a workshop. Artisan 's high quality and high performance allow you to unleash your creativity. Artisan is not just an upgrade to Snapmaker 2.0 , but sets a new benchmark for 3-in-1 3D printers.

New generation linear module

Linear module motion systems are the backbone of any specific manufacturing machine, and the performance of the motion system is closely related to the overall performance of the machine. Linear tracks are widely used in industrial fields, such as industrial robots and transportation equipment, and are devices that ensure that equipment strictly follows the required path in both vertical and horizontal directions. In the case of the Snapmaker 3D printer , this refers to the tool head module for 3D printing , laser engraving and cutting , and CNC engraving .

.jpg)

How does the new generation of linear modules achieve micron-level precision? It's about positioning the cutter head correctly, which depends on two fundamental components of the linear guide: the bearing and the drive unit. At Artisan , the R&D team improved these two components, optimizing the performance of the linear module. In Snapmaker 2.0 , the bearing is a combination of a linear bar and a pulley. Linear bars are used in many 3D printers on the market. However, linear bars have limited capabilities, failing to provide smoother movement and higher precision. On the other hand, linear guides allow for more rigid motion mechanisms. They are less susceptible to vibration, thus reducing printing problems such as ringing.

.jpg)

Replacing conventional linear guides, Snapmaker brings industrial-grade drive technology to 3D printers —steel guides, manufactured through micron-level CNC grinding, are embedded in Artisan 's linear modules.

Similar to the drive unit, we've applied Gates' high-end synchronizing belts to optimize leads on the X and Y axes, improving power transmission efficiency while maintaining high precision and low noise levels. Compared to the transport lead screws used in the AT model , Artisan 's X and Y axis leads have increased from 20mm to 40mm.

Overall, improvements to the bearings and drive units have brought the performance of the Artisan linear module to a new level. The straightness and flatness errors are now within 0.04 mm, while the positioning accuracy is within 0.1 mm. How does it perform in 3D printing and CNC engraving ? Snapmaker Artisan can achieve high-quality printing at higher speeds through its superior linear module. If the speed is increased, dimensional accuracy of ±0.1 mm can be achieved at high speeds of 150 mm/s to 180 mm/s [1]. The new linear module also ensures the stability of CNC machining.

In short, these upgrades result in significant improvements in precision, rigidity, and durability, providing you with a fast, accurate, and stable manufacturing experience.

300°C Dual-Nozzle 3D Printing Module

Similar to the drive unit, we've applied Gates' high-end synchronizing belts to optimize leads on the X and Y axes, improving power transmission efficiency while maintaining high precision and low noise levels. Compared to the transport lead screws used in the AT model , Artisan 's X and Y axis leads have increased from 20mm to 40mm.

Overall, improvements to the bearings and drive units have brought the performance of the Artisan linear module to a new level. The straightness and flatness errors are now within 0.04 mm, while the positioning accuracy is within 0.1 mm. How does it perform in 3D printing and CNC engraving ? Snapmaker Artisan can achieve high-quality printing at higher speeds through its superior linear module. If the speed is increased, dimensional accuracy of ±0.1 mm can be achieved at high speeds of 150 mm/s to 180 mm/s [1]. The new linear module also ensures the stability of CNC machining.

In short, these upgrades result in significant improvements in precision, rigidity, and durability, providing you with a fast, accurate, and stable manufacturing experience.

300°C Dual-Nozzle 3D Printing Module

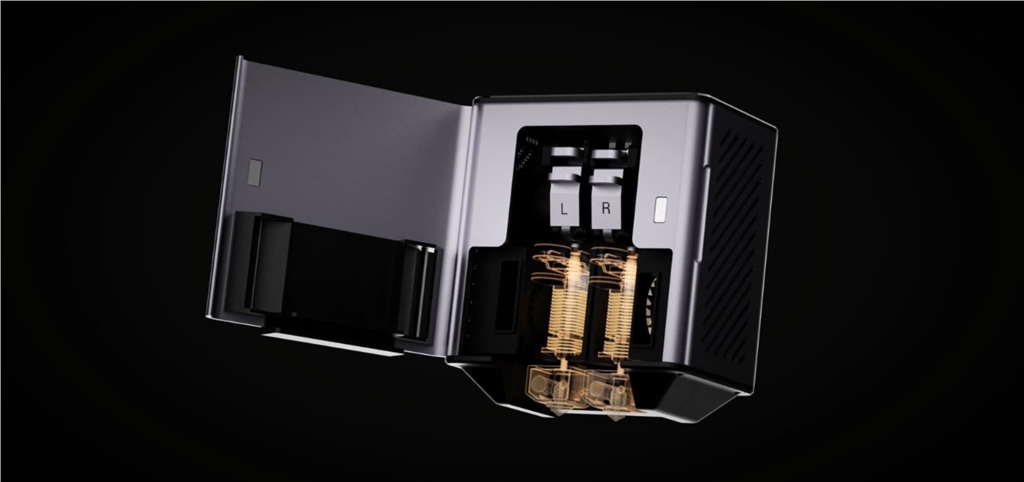

The dual-printer 3D printing module has always been one of the R&D team's development projects, opening up a world of 3D printing with multiple materials and colors. Compared to Snapmaker 2.0 , Artisan has achieved comprehensive improvements in printing speed, accuracy, filament compatibility, and accessibility.

.jpg)

The switching mechanism and automatic bed leveling scheme are key to the design of dual-nozzle module. In most dual-nozzle systems on the market, the two nozzles are typically mechanically raised and lowered, which is usually time-consuming, requiring the tool head to move along the X-axis and strike both ends to complete the switching. In Artisan , the nozzle module is automatically raised by a lead screw stepper motor, improving switching efficiency and eliminating the noise associated with mechanical raising.

Artisan automatically levels the heated bed and calibrates the Z-offset of the two dual printheads, while calibrating the XY-offset using a semi-automatic program. Enjoy perfect adhesion and alignment for two-material or two-color printing in just three steps. Built-in springs near the nozzles help facilitate calibration and prevent the nozzles from hitting the bed or the print. A double-sided printing build plate is even available, allowing easy switching between conventional materials like PLA and PETG and flexible materials like TPU . One side of the build plate is glossy glass, and the other is PEI coated. A photoelectric switch is used to achieve automatic bed leveling.

However, switching materials during printing is possible if using a single printhead. But there are a few things to keep in mind. Different types of filaments require different nozzle temperatures to function optimally, and the temperature needs to be adjusted before manually changing materials. Otherwise, temperatures (too high or too low) can cause carbonization, followed by nozzle clogging and insufficient extrusion.

Switching to two independent nozzles allows heating up to 300°C. You can work with a wider range of materials, such as soluble materials like PVA and HIPS, Breakaway filament, and even tough nylon . Removing support material is never a pleasant task and can even leave rough spots on the print. Soluble support materials can save you from this nightmare. Breakaway filament provides the same support as regular materials but is easier to remove and requires no further post-processing. You can boldly print models with complex structures. Different nozzle sizes can also be changed to suit your needs.

10W Laser Engraving and Cutting Module

Artisan comes standard with a 10W laser. More importantly, it can laser engrave objects as small as 400mm x 400mm x 400mm. The laser beam splitter and beam-shaping optics in the laser module provide high power of 10W and ultra-fine laser focusing at 0.05 x 0.2mm. A triangulation system and a wide-angle lens calculate the material thickness, autofocusing in seconds and providing instant preview on the Snapmaker Luban. The 10W laser module can engrave at speeds up to 6000mm/mins, and can cut paulownia wood up to 8mm thick in a single pass.

However, switching materials during printing is possible if using a single printhead. But there are a few things to keep in mind. Different types of filaments require different nozzle temperatures to function optimally, and the temperature needs to be adjusted before manually changing materials. Otherwise, temperatures (too high or too low) can cause carbonization, followed by nozzle clogging and insufficient extrusion.

Switching to two independent nozzles allows heating up to 300°C. You can work with a wider range of materials, such as soluble materials like PVA and HIPS, Breakaway filament, and even tough nylon . Removing support material is never a pleasant task and can even leave rough spots on the print. Soluble support materials can save you from this nightmare. Breakaway filament provides the same support as regular materials but is easier to remove and requires no further post-processing. You can boldly print models with complex structures. Different nozzle sizes can also be changed to suit your needs.

10W Laser Engraving and Cutting Module

Artisan comes standard with a 10W laser. More importantly, it can laser engrave objects as small as 400mm x 400mm x 400mm. The laser beam splitter and beam-shaping optics in the laser module provide high power of 10W and ultra-fine laser focusing at 0.05 x 0.2mm. A triangulation system and a wide-angle lens calculate the material thickness, autofocusing in seconds and providing instant preview on the Snapmaker Luban. The 10W laser module can engrave at speeds up to 6000mm/mins, and can cut paulownia wood up to 8mm thick in a single pass.

Laser-engraved bottle created by group member Michael Mikkelson; chess game created by group member Lennart Lamoller.

200W CNC carving and cutting

Artisan ’s 200W CNS module is designed to meet the precision machining needs of hardwoods such as beech and walnut, jade and other hard materials. Compared to Snapmaker 2.0 , Artisan ’s 200W CNS module has 300% more power and 50% more maximum spindle speed. Machining speed on hardwoods such as beech is increased by 6 times[2] and dimensional accuracy is 0.2 mm[3]. The runout within the chuck is now 0.02 mm, compared to 0.05 mm with the 50W CNS module of Snapmaker 2.0 .

Artisan ’s 200W CNS module is designed to meet the precision machining needs of hardwoods such as beech and walnut, jade and other hard materials. Compared to Snapmaker 2.0 , Artisan ’s 200W CNS module has 300% more power and 50% more maximum spindle speed. Machining speed on hardwoods such as beech is increased by 6 times[2] and dimensional accuracy is 0.2 mm[3]. The runout within the chuck is now 0.02 mm, compared to 0.05 mm with the 50W CNS module of Snapmaker 2.0 .

.jpg)

Choosing the right cutting tools is crucial for CNC machining. The new CNC module comes equipped with three CNC end mills: two flat end mills (single-edged and double-edged) plus a straight-flute V-head, enabling you to achieve efficient machining in CNC processes .

Snapmaker was the first manufacturer to introduce embedded steel guide linear modules into the desktop 3D printer industry and to provide this industrial technology to makers around the world.

Did you enjoy this sharing? Snapmaker offers more than just 3D printing . Contact us now to learn more about the Snapmaker series of 3-in-1 3D printers .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

[1] The test results were obtained by printing a 100 mm × 100 mm × 100 mm cube using a PLA and a 0.4 mm nozzle. Dimensional accuracy may vary depending on test conditions and repeated calculations of the product, and is for reference only.

[2] The recommended speed for the maximum 50W CNC module is 1000 mm/min, decreasing by 1 mm, and the recommended speed for the 200W CNC module is 3000 mm/min, decreasing by 2 mm.

[3] This data is obtained from beech wood cutting and may vary due to different testing conditions and repeated calculations of the product. It is for reference only.

Snapmaker was the first manufacturer to introduce embedded steel guide linear modules into the desktop 3D printer industry and to provide this industrial technology to makers around the world.

Did you enjoy this sharing? Snapmaker offers more than just 3D printing . Contact us now to learn more about the Snapmaker series of 3-in-1 3D printers .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

[1] The test results were obtained by printing a 100 mm × 100 mm × 100 mm cube using a PLA and a 0.4 mm nozzle. Dimensional accuracy may vary depending on test conditions and repeated calculations of the product, and is for reference only.

[2] The recommended speed for the maximum 50W CNC module is 1000 mm/min, decreasing by 1 mm, and the recommended speed for the 200W CNC module is 3000 mm/min, decreasing by 2 mm.

[3] This data is obtained from beech wood cutting and may vary due to different testing conditions and repeated calculations of the product. It is for reference only.