[3D Scanning Application] Using 3D scanning and CAD simulation to help customers repair SAG grinding machines - SHINING 3D X ATEGROUP

3D scanning is an efficient method for modern reverse engineering, iterative design, and other CAD-related applications . In industrial maintenance and repair, accurate measurements are crucial for troubleshooting equipment failures and improving operational efficiency. Metrological 3D scanners like the FreeScan UE 11 are ideal tools in these situations because they can capture accurate and precise 3D data in the shortest possible time.

How did ATEGROUP use the FreeScan UE 11 3D scanner to repair a component of a grinding mill? Let's take a look at their case study!

Problem: Damaged wheel hub

ATEGROUP's customers use SAG mills to grind materials throughout their value chain. While details were withheld to maintain customer anonymity, it's clear that material preparation remains a critical part of production. The quality of the materials forms the foundation for the quality of the final product.

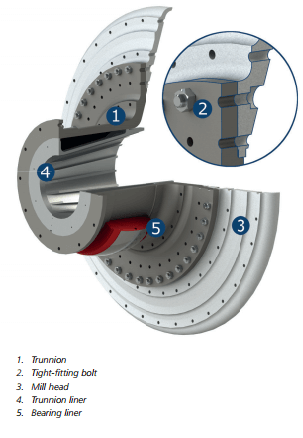

The customer discovered that their SAG mill was damaged; material was leaking from the machine during the grinding process. They quickly found that the machine's feed and discharge hubs, critical components responsible for material transfer, had cracked.

The team faces serious problems due to the leak of materials. This not only concerns operational efficiency but also employee safety.

Solution

For wheel rim repair, the customer chose ATEGROUP, a Colombian company that provides 3D scanning and reverse engineering services. They utilize a range of SHINING 3D scanners to offer these services.

ATEGROUP set two goals for this project:

1. Determine the most suitable technology for reinforcing wheel hubs.

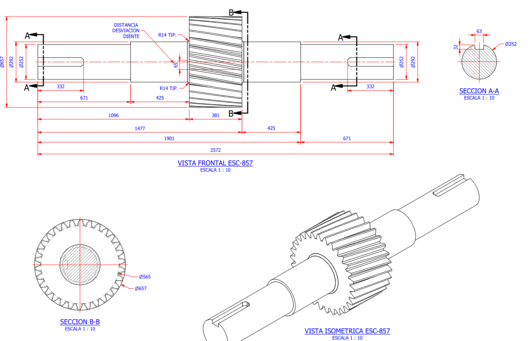

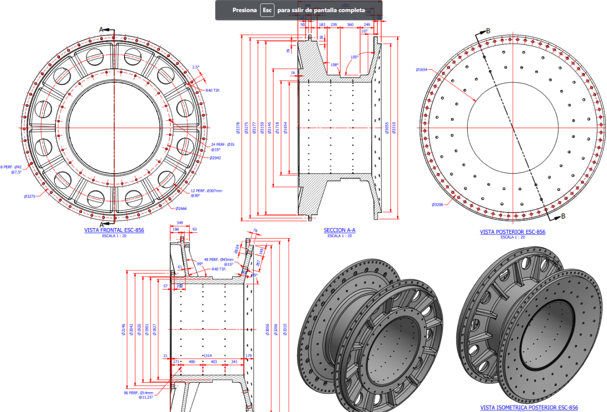

2. Generate accurate 2D drawings of wheel hubs and drive units.

I. 3D Scanning

First, ATEGROUP performed 3D scanning of the components of the SAG mill. For large components ranging from approximately 2.5 to 3 meters in length, the portability and speed of the 3D scanner are crucial. The team was able to easily perform 3D scanning around the entire mill using the lightweight FreeScan UE 11.

Then, after placing markers on the metal surface of the mill, the team quickly captured additional data using a scanner. The FreeScan UE 11 project used 11 intersecting laser beams to capture data at a rate of 1.35 million points per second.

II. Reverse Engineering

Based on the 3D point cloud obtained in the previous step, the team then proceeded with the reverse engineering phase. They processed the scanned data and used Geomagic Design X to extract the required measurements and geometry.

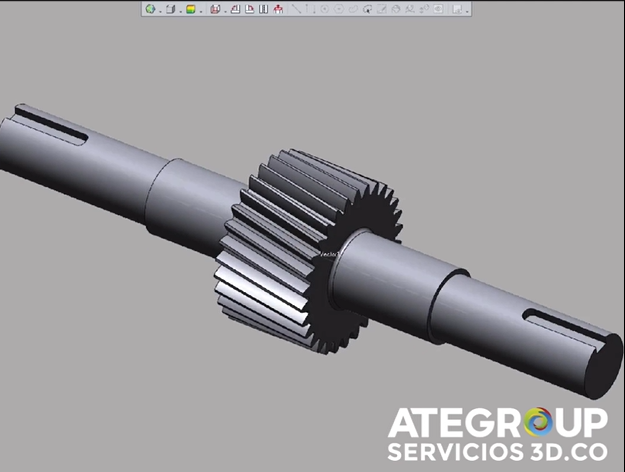

ATEGROUP meticulously reconstructed the parts in a digital 3D environment: parts in CAD software after 3D scanning and simulation analysis.

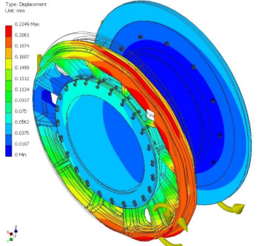

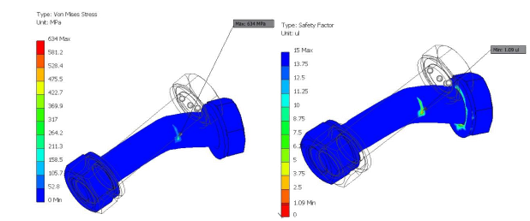

III. Simulation Analysis

Finally, ATEGROUP engineers used a scan-based CAD model to perform simulation analysis to determine the optimal repair solution. Using their simulation software, they replicated the operating conditions and applied stress factors to the digital hub, allowing them to analyze the behavior of each component under different scenarios, assess potential failure points, and identify the most effective repair method.

3D scan view used for simulation analysis in software

result

Using FreeScan UE 11, ATEGROUP can achieve two goals after reverse engineering and simulation analysis:

1. The most effective and robust wheel hub repair solution was proposed.

2. Provided accurate 2D drawings of parts for subsequent production.

Regarding the first point, the team recommends using A36 steel lining plates. This provides the correct structural support for resolving the leakage issue, and the detailed and accurate 2D drawings allow the customer to ensure the correct fabrication of the components ; it saves the customer significant time and resources compared to manual measurement and drawing .

With 3D scanning and suitable software, engineers can generate 2D files with just a few clicks , freeing up more time for other, more productive projects.

Digital simulation is an effective method for providing durable and robust repairs for industrial parts and machinery. Accurate simulation requires precise 3D data.

The FreeScan UE 11 3D scanner was used to capture metrology-level data from the SAG mill. ATEGROUP was able to quickly find the most suitable solution for the customer, resolve critical issues, restore production, and ensure employee safety.

SHINING 3D 's precise and portable 3D measurement solutions can help simplify the maintenance and repair process.

-Contact Us-

Find out which 3D scanner meets your needs.

SanDima offers more than just 3D printing . Contact us today to learn more about the SHINING series 3D scanners .

Follow our fan page and stay up-to-date with the latest news:

Facebook: https://www.facebook.com/3dmart.com.tw

Instagram: https://www.instagram.com/3dmart

LinkedIn: https://www.linkedin.com/company/3dmart/

References