[3D Printing] Prusa Core One: A Highly Efficient and Reliable Consumer Product

The Prusa Core One retains its slightly industrial look, but its design is more refined, something that traditional frame bed slings lack.

CORE One offers ultra-fast CoreXY printing with the same quality as consumers expect from the MK4S, while also providing an upgrade path, making it the best choice for any professional seeking a 3D printing solution.

Of course, the company has released other CoreXY systems.

For example, the Original Prusa XL, a tool-changing type, is a recommended machine in this category.

However, with a suggested retail price of around $2,500 for a pre-assembled unit, the XL is clearly a machine geared towards professional consumers.

It's truly remarkable that Prusa has achieved such a price point. Furthermore, MK4S owners will eventually be able to upgrade their machines for less than half the price of a Core One kit.

The Prusa Core One is a brand-new, fully enclosed CoreXY 3D printer that breaks away from the company’s usual open bed design.

The CORE One is designed to incorporate all the speed and features of the MK4S and XL into a newly developed and redesigned machine—hering in the next era of 3D printing.

With Core One, it takes less than 10 minutes from unpacking, powering on, to starting to print; it's incredibly fast and simple.

The company’s signature tool head, Nextruder, has helped eliminate the previously steep learning curve for 3D printing with its “always perfect first layer” and other progressively improved user-friendliness.

Even Wi-Fi connectivity has been simplified through the NFC setup process of the Prusa app, which will be released with the MK4S in the summer of 2024.

The company’s software, Prusa Slicer, is also steadily improving, even drawing inspiration from Bambu Studio and implementing workflows familiar to Bambu users, such as multi-bed slicing.

Functionally, the Core One’s first print is just as smooth as the MK4S, requiring only a few automatic calibration procedures and minimal user intervention to test the load cells and wire sensors.

Furthermore, the machine's packaging and shape are remarkably compact.

Previously, the large enclosure that had to be installed around the MK4S took up a lot of space, but the new Core One can easily accommodate most of your shelving units.

Prusa stated that Core One occupies 50% less space than the previous combination, while its build volume has increased by 30%, which is remarkable.

One more small detail: the Core One's plug doesn't protrude directly from the back of the machine, thus saving valuable space.

This shows that the Prusa team has given careful thought to how the system can save space.

Despite its smaller size, the Core One has a build volume of 220 x 250 x 270 mm, which is 30% taller than the MK4S, and Prusa says it is even 15-20% faster.

Using the Prusa Slicer and early access profile for slice display, with the preset 0.20 mm “SPEED” profile and Prusament PLA, the expected speed of sample parts was improved by approximately 13% - 6 hours and 33 minutes, compared to less than 7 hours and 35 minutes.

The printing time for Benchy has been reduced from 36 minutes to 33 minutes, approximately 8% faster (this includes cold heating time and pre-print checks).

One of the most popular aspects of Prusa machines is their ability to be upgraded, tuned, and customized to suit specific workflows.

While the Prusa CORE One looks much more refined than the previous open-frame design, there are still plenty of upgrade options.

It supports the MMU3 for multi-wire printing and includes a new GPIO expansion board that can integrate accessories such as active LEDs and wired DSLR camera triggers.

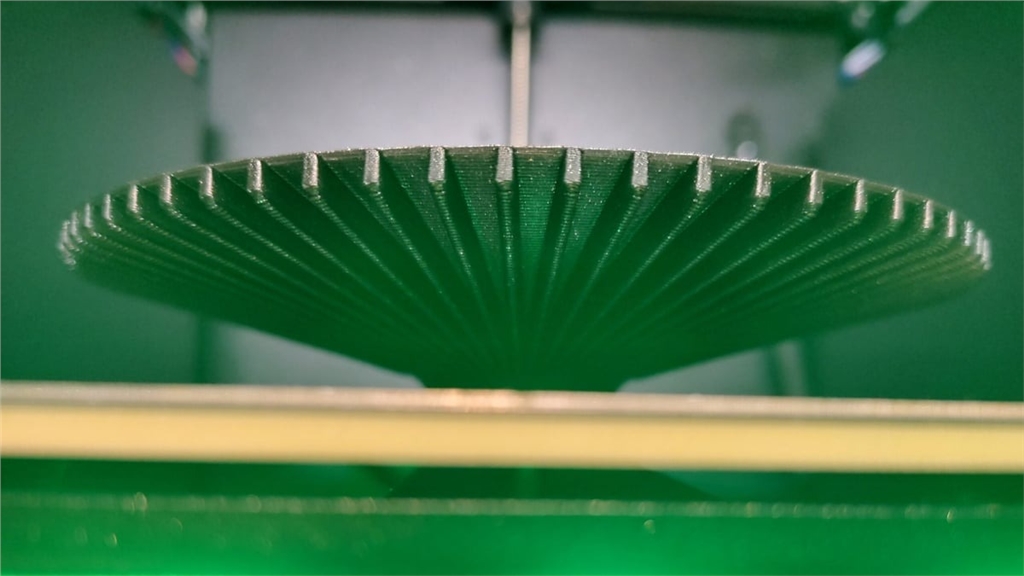

The two main design features of Core One are: first, it is a CoreXY machine; second, it uses a fully enclosed frame.

The casing is made of solid steel profiles to ensure rigidity. Meanwhile, Prusa chose a durable polymer for the doors and sides instead of glass, stating that this material is stronger and safer than the glass alternatives used in many high-end 3D printers.

Another point is that the XY gantry is made of steel, not a mixture of steel and aluminum, to ensure that there are no differences due to thermal expansion.

One feature of this design is that the door can be opened 180° for easy entry and exit.

In addition, you can flip the door's position to switch it from opening from left to right to opening from right to left, allowing you to adjust it according to your workspace layout.

Prusa introduced powerful cooling capabilities to the Nextruder through the MK4S, which has been carried over to the Core One, where its 75º overhang performance is outstanding.

Durability tests of the Scandic Plate were conducted using the Prusament Galaxy PLA printer, and the results were just as impressive as those of the MK4S.

Concerns that the enclosure might impair the performance of low-temperature materials such as PLA are reasonable, but the Core One features active cavity temperature control thanks to its dual-enclosure fans and top vents.

At the Core One Formnext presentation, the company stated that during testing, the indoor temperature was maintained at 27 ºC with the laboratory chamber door closed.

This feature will eliminate the need for you to remember to open the printer door and top cover.

When you look at the printhead of the CORE One, it looks very similar to the printhead on the MK4S, mainly because the cooling system provides the same 360° airflow.

Therefore, it is once again equipped with high-flow nozzles to meet the high-speed requirements of printers.

The design of CORE One is entirely new, highlighting the shift in 3D printer design methodology that Prusa first saw in the XL.

This is a significant evolution, meeting the expectations of many users through its fully enclosed CoreXY design and multi-wire compatibility.

Did you enjoy this sharing? Contact us now to learn more about Original Prusa.

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | Threads