[3D Printing News] Prusa's latest product, the Original MK4, has arrived with a bang!

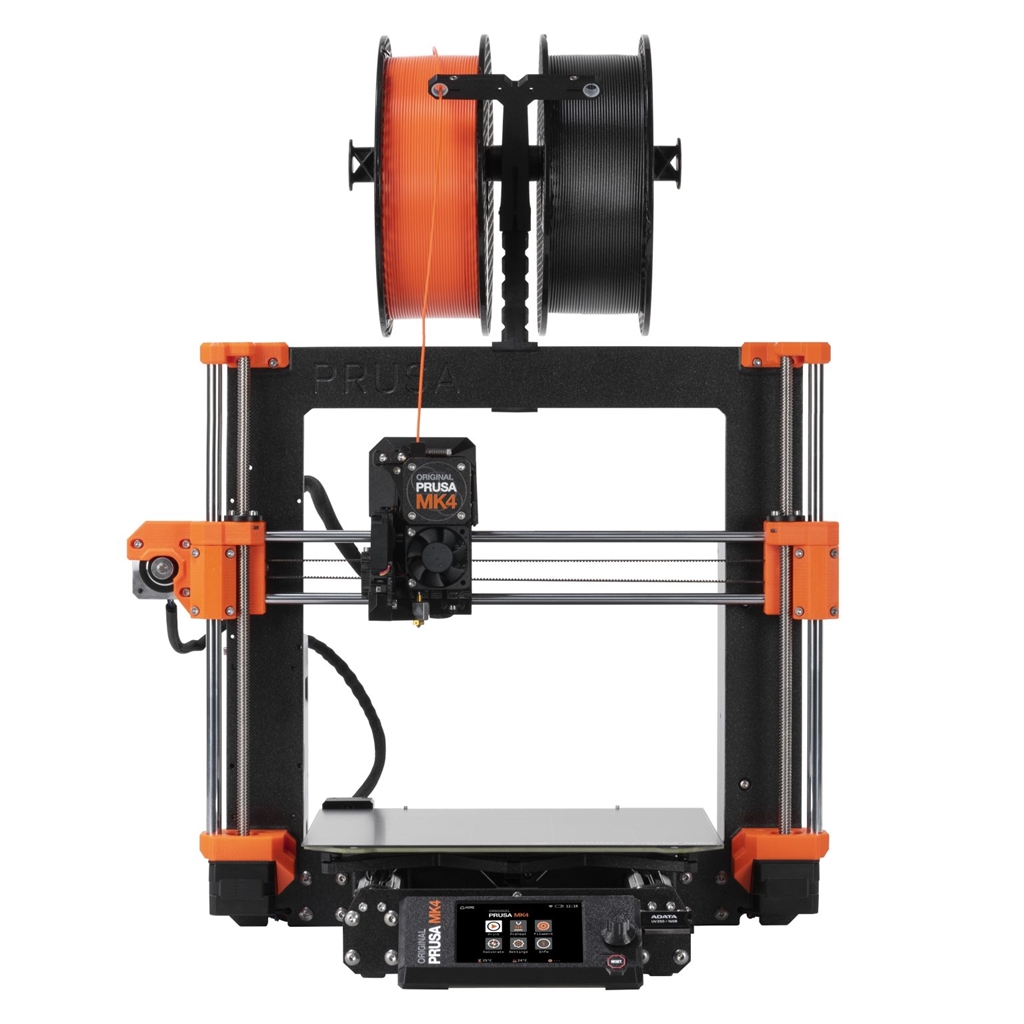

Czech-based 3D printing manufacturer Prusa Research has announced its latest desktop 3D printer, the Original Prusa MK4 . This new machine is another success story following the MK3, which sold over 350,000 units globally over the past five years and won the "3D Printer of the Year" award four times consecutively between 2019 and 2022.

While the Original Prusa MK4 is built on the MK3, Prusa emphasizes that the product incorporates numerous improvements. Josef Prusa, founder and CEO of Prusa Research, says, "At first glance, the MK4 may seem similar, but in fact, we've tweaked and improved it, even replacing 90% of the components. The MK4's key goal is to improve the user experience, with a variety of new features that primarily make the printing process faster, easier, and more intuitive, offering a wider range of printing possibilities. The MK4 makes it easier for the average user to try 3D printing technology; they're not interested in printers that require tweaking and fiddling, they just want to print."

While the Original Prusa MK4 is built on the MK3, Prusa emphasizes that the product incorporates numerous improvements. Josef Prusa, founder and CEO of Prusa Research, says, "At first glance, the MK4 may seem similar, but in fact, we've tweaked and improved it, even replacing 90% of the components. The MK4's key goal is to improve the user experience, with a variety of new features that primarily make the printing process faster, easier, and more intuitive, offering a wider range of printing possibilities. The MK4 makes it easier for the average user to try 3D printing technology; they're not interested in printers that require tweaking and fiddling, they just want to print."

MK4 main features

The MK4 uses Prusa's new xBuddy board, a 32-bit STM32-driven motherboard, replacing the older EINSY RAMBo board used in the MK3. This new motherboard, considered the cornerstone of the MK4 , was designed, manufactured, and tested in-house by Prusa .

Designed to maximize safety and reliability, the xBuddy offers several new features compared to its predecessor. For example, it integrates dual voltage measurement, heater current measurement, and total input current measurement on the 24V branch. Furthermore, to maximize printer safety, the motherboard automatically disconnects the hot-end heater if the current exceeds 2.8A, and also disconnects the heater and heated bed power supplies when the total current exceeds 15A. The motherboard also supports power-off resume printing and includes four thermistors (hot end, off-center, heated bed, and ambient).

It also uses the TMC2130-LA driver and is equipped with many ports, including an ESP-01 Wi-Fi port, an Ethernet port, a service USB-C port, an I2C port, an accelerometer port (unfilled), a Multi-Material Upgrade 3 (MMU3) port, and a Nextruder port.

Designed to maximize safety and reliability, the xBuddy offers several new features compared to its predecessor. For example, it integrates dual voltage measurement, heater current measurement, and total input current measurement on the 24V branch. Furthermore, to maximize printer safety, the motherboard automatically disconnects the hot-end heater if the current exceeds 2.8A, and also disconnects the heater and heated bed power supplies when the total current exceeds 15A. The motherboard also supports power-off resume printing and includes four thermistors (hot end, off-center, heated bed, and ambient).

It also uses the TMC2130-LA driver and is equipped with many ports, including an ESP-01 Wi-Fi port, an Ethernet port, a service USB-C port, an I2C port, an accelerometer port (unfilled), a Multi-Material Upgrade 3 (MMU3) port, and a Nextruder port.

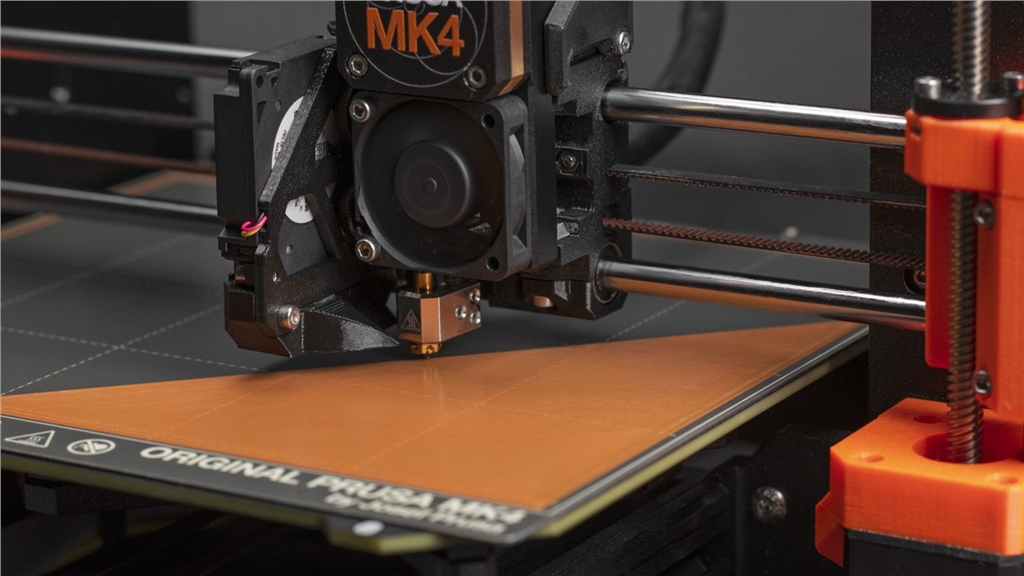

The Prusa Nextruder, a new generation extruder, is another significant update to the MK4 . A smaller, lighter version of the Nextruder is already used in the Original Prusa XL , while the MK4 's Nextruder features a larger load cell sensor. This sensor precisely sets the distance between the nozzle and the printing platform paper by measuring the tension inside the extruder. This process allows the MK4 to automatically print a perfect first layer without the need for constant Z-axis adjustments or any manual nozzle adjustments.

The Nextruder port on the mainboard also offers users greater convenience. Previously, older models directly connected extruder components to the mainboard, making component replacement a complex and time-consuming process. However, with the MK4 and its new connector disconnect board, the LoveBoard can directly connect to all extruder components inside the Nextruder, significantly speeding up the extruder component replacement process.

The MK4 's quick-change nozzle design also saves users time when modifying the hot end. Thumb screws are added to both sides of the Nextruder, allowing the entire hot end to be quickly and easily removed and replaced after loosening. After modification, the load cell sensor will quickly and automatically calibrate at the start of the next print run. The Nextruder-V6 adapter and compatible V6 nozzles, including hardened and high-flow models, can be used with the MK4 . Prusa has also released a range of nozzles (from 0.25 to 0.8), with more models expected to be available in the future.

The Nextruder port on the mainboard also offers users greater convenience. Previously, older models directly connected extruder components to the mainboard, making component replacement a complex and time-consuming process. However, with the MK4 and its new connector disconnect board, the LoveBoard can directly connect to all extruder components inside the Nextruder, significantly speeding up the extruder component replacement process.

The MK4 's quick-change nozzle design also saves users time when modifying the hot end. Thumb screws are added to both sides of the Nextruder, allowing the entire hot end to be quickly and easily removed and replaced after loosening. After modification, the load cell sensor will quickly and automatically calibrate at the start of the next print run. The Nextruder-V6 adapter and compatible V6 nozzles, including hardened and high-flow models, can be used with the MK4 . Prusa has also released a range of nozzles (from 0.25 to 0.8), with more models expected to be available in the future.

Another key feature of the MK4 's high printing speed is its use of input shaping and pressure-driven technologies, which can reduce printing time by 75% while maintaining excellent print quality. For example, as shown in the video below, a sample print that takes 80 minutes on the MK3 can now be completed in 20 minutes.

The new MK4 also features a new graphical LCD interface, replacing the previous segmented LCD. The color screen supports G-code thumbnails, long text, graphics, and QR codes. Additionally, an RGB status bar has been added below the LCD screen, with a set of programmable RGB LEDs using various colors to display the printer's current status. A USB-A port has also been added next to the display for storing G-codes using USB devices.

Along with the MK4 , Prusa also announced the new MMU3, which is compatible with both the MK3S+ and MK4 models. This optional add-on allows single-extruder printers to print up to five colors at a time, and the MMU3 offers improved reliability and ease of control compared to previous versions.

Along with the MK4 , Prusa also announced the new MMU3, which is compatible with both the MK3S+ and MK4 models. This optional add-on allows single-extruder printers to print up to five colors at a time, and the MMU3 offers improved reliability and ease of control compared to previous versions.

Technical Specifications

Did you enjoy this sharing? Sandima offers more than just 3D printing . Contact us now to learn more about the Original Prusa MK4 3D printer .

| Build volume | 250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in |

| wire diameter | 1.75 |

| floor height | 0.05-0.30mm |

| motherboard | Custom 32-bit xBuddy electronics with STM32 |

| Stepper driver | Trinamic 2130 |

| Stepper motor | Precision 0.9° X, Y stepper motors (to prevent VFA) |

| Extruder | Nextruder extruder, direct drive, compatible with E3D V6 (with adapter) |

| Extruder electronic components | Custom-designed junction boards for connecting fans, thermistors, and other components. |

| Wire path | Aluminum heat sink, all-metal hot end, no PTFE pipe |

| drive system | Nextruder planetary gear system, 10:1 gearbox ratio |

| Nozzle diameter | Nozzle diameter 0.4mm (preset) / Other nozzle diameters supported |

| Nozzle maximum temperature | 300 °C |

| Maximum heated bed temperature | 120 °C |

| LCD screen | 3.5-inch 65k color graphics screen |

| Connection method | LAN, optional ESP Wi-Fi module (supplied with device). |

| File transfer | USB / LAN / Internet access via Prusa Connect |

| Advanced Sensors | Wire sensor, Loadcell sensor, Power panic, 4 high-precision thermistors (genuine Semitec) + fan motor RPM monitoring |

| Printing Platform | Magnetic heated bed with removable PEI spring steel sheets. |

| Printing platform bed calibration | Automatic wire bed leveling (only in the printing area) |

| Support cable | PLA, PETG, ABS, ASA, Flex, HIPS, PA, PVA, PC, PP, CPE, PVB, NGEN composite materials, etc. |

| Equipment dimensions (excluding spools) | 7 kg, 500×550×400 mm; 19.6×21.6×15.7 inches (X×Y×Z). |

| power supply | 240W, custom-made by Delta, equipped with Power Panic HW |

| Power consumption | PLA settings: 80W ABS setting: 120W |

Did you enjoy this sharing? Sandima offers more than just 3D printing . Contact us now to learn more about the Original Prusa MK4 3D printer .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References