[Vacuum Forming Application] Perfectly covers right-angled shapes, improving demolding effect with two key features!

Vacuum forming not fitting well? Mold cooling too difficult to disassemble? Now no more manual drilling required, and even 90-degree angled objects are no problem. Perfect and tight coverage, two magic weapons to improve demolding efficiency!

The technical principle of vacuum forming machines is to heat and soften a sheet of plastic material, then press it down to form a vacuum injection sheet that is attached to the surface of a blister mold. The material is then shaped at high temperature and cooled to set its shape. Vacuum forming machines are now widely used in applications such as silicone demolding , food processing , mold development , blister packaging , and medical aids .

During the vacuum forming process, the smooth flow of air between the material sheet and the processed item, as well as the complexity of the item's shape, are the two main factors affecting the quality of vacuum forming. To improve quality, manual hole cutting is usually used, or 90-degree right-angle cuts are avoided as much as possible before designing the mold to ensure a tight fit between the material sheet and the item. ( Click to see: 3 tips for vacuum forming: Elevating the quality of blister packaging! )

To improve the release effect, there are two other methods to choose from:

• Elastic soft material sheet

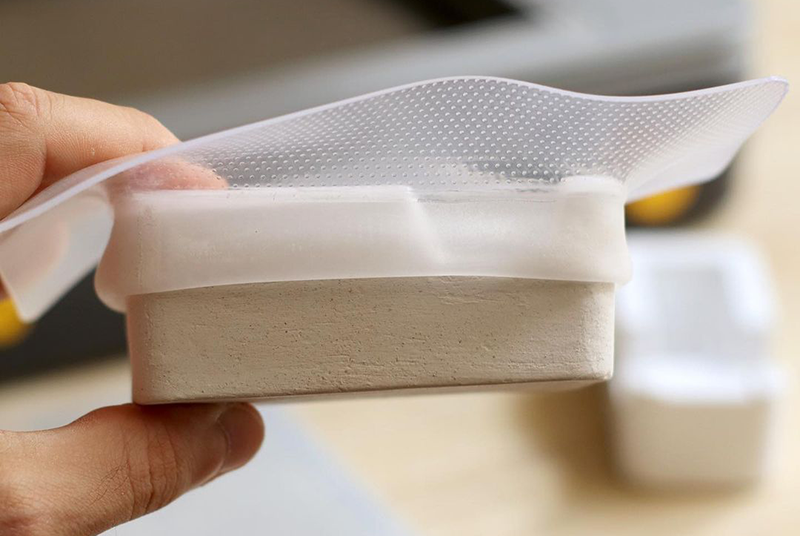

Choosing a flexible, soft material sheet results in a better wrapping effect when pressed down instantly after heating compared to other rigid sheets. Furthermore, because it retains its original elasticity after cooling, it makes removing objects from the sheet much easier. ( Click to see: DIY Whiskey Spherical Ice Mold – Create Your Own Ice Cubes! )

(Using FormBox Flex elastic material sheets for vacuuming allows for easy demolding even after cooling and setting.)

• Densely perforated metal platform

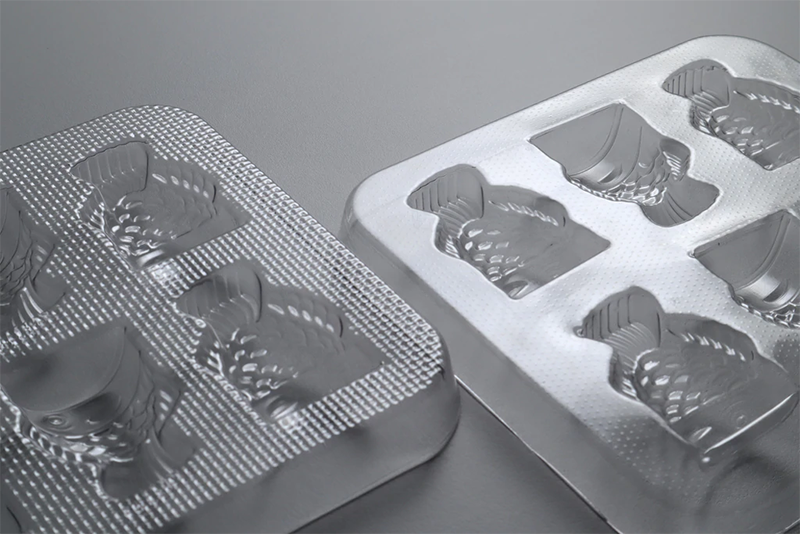

The Mayku Pro Mesh metal work platform is made of ultra-fine 1.2mm stainless steel with more than 1,000 small holes, which allows more air to escape from around the vacuum forming mold compared to the perforated work platform originally equipped with the Formbox machine .

(Left side of the image: Vacuum forming effect using a Pro Mesh metal workbench . Right side of the image: Vacuum forming effect using a Formbox basic equipment workbench.)

The Pro Mesh 's dense array of tiny holes allows air to flow smoothly through the mesh, resulting in a tighter fit of the edges during vacuum forming and a sharper, cleaner finish. The fish scales on the taiyaki surface shown in the image above also contribute to this, creating a more refined texture while maintaining a smooth surface, allowing for smooth forming even with complex shapes. ( Click to see: Silicone Flip-Flops, Self-Manufacturing Production Line, No Outsourcing! )

Did you enjoy this sharing session? By experimenting with the properties of different materials and cleverly combining them during the processing, we can break away from traditional manufacturing concepts and improve the success rate of vacuum forming. By adjusting the tools used, even the most intricate structural shapes can be presented with precision. 3D Printing offers more than just 3D printing . Contact us now to learn more about vacuum forming applications.

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/