[Thermoforming Applications] Vacuum Forming VS Pressure Forming: What's the Difference? We'll Tell You All About It!

Vacuum forming and pressure forming are both thermoforming technologies. However, they differ significantly in terms of "finished product appearance," "technical principles," "common materials," and "application scope." The video by the founder of Mayku compares these differences side-by-side, and this article also provides a comparative chart of practical applications for a more comprehensive evaluation!

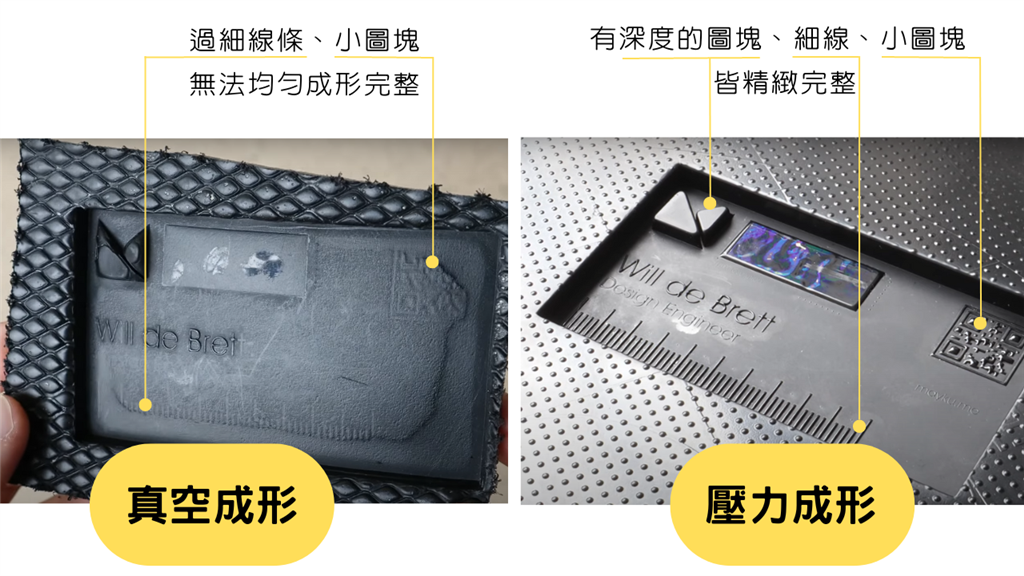

【Finished Product Effect】

[Technical Principles]

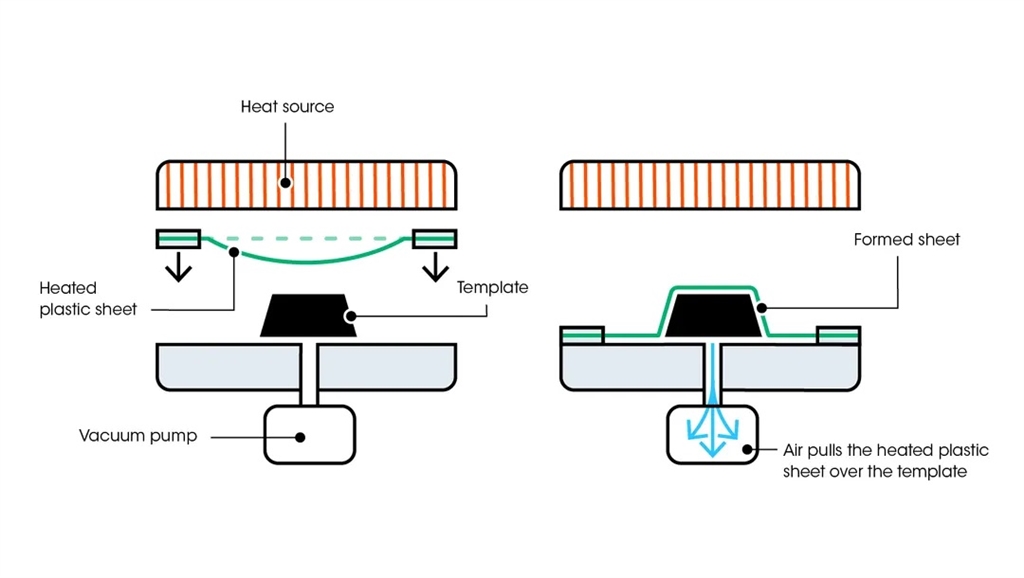

- Vacuum forming is the most traditional thermoforming method, which involves using a vacuum to remove air between the heated plastic material and the mold. By utilizing a vacuum, the plastic material can be perfectly molded, allowing for the capture of details, shapes, and other features.

First, a sheet or roll of plastic is loaded onto the material carrier of the vacuum forming machine and heated from above. Once sufficiently softened, the vacuum forming tool is pulled close to the template to form a seal. A vacuum pump then creates a vacuum, pulling the plastic sheet onto the mold of the vacuum forming tool. After the formed plastic shell cools and solidifies, it is removed by hand or with air. The resulting plastic shell can be trimmed or otherwise modified to meet specific specifications.

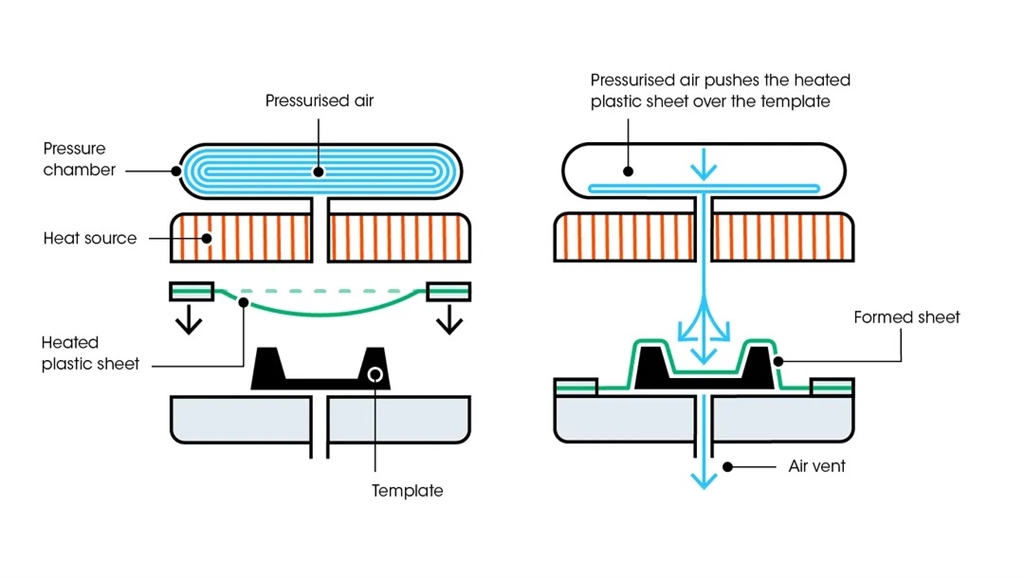

Compression molding is the process of using air pressure to create molds or parts on heated plastic sheets . It can create parts or tools with high detail and texture.

First, the plastic sheet is inserted into the compression molding machine, positioned above the mold. Heating is then applied from above. Once the appropriate temperature is reached, pressurized air pushes the plastic sheet onto the mold. Ventilation vents expel any incoming air. Once fully cooled and hardened, the plastic sheet is removed from the mold, producing a plastic shell that can be modified and adjusted to specific specifications.

【 Common Materials 】

thermoformed plastic sheetsVacuum forming and pressure forming are both suitable for the same plastic sheets, although pressure forming can typically use thicker plastic sheets than vacuum forming and can be used for thicker parts.

High-impact polystyrene ( HIPS ): stable, low-cost, and impact-resistant .

EVA : It has low-temperature toughness and UV resistance .

PETG : Good hardness, chemical resistance, impact resistance, transparency and ductility, suitable for food-grade tools or parts.

Low -density polyethylene (LDPE): It can withstand high temperatures, is resistant to chemical corrosion, and is soft and elastic .

Other materials used in pressure forming and vacuum forming include:

Acrylic (PMMA)

Acrylonitrile butadiene styrene (ABS)

Polycarbonate (PC)

Polyethylene (PE)

Polypropylene ( PP )

Polystyrene (PS)

Polyvinyl chloride (PVC)

Other plastic sheets, etc.

Thermoforming template

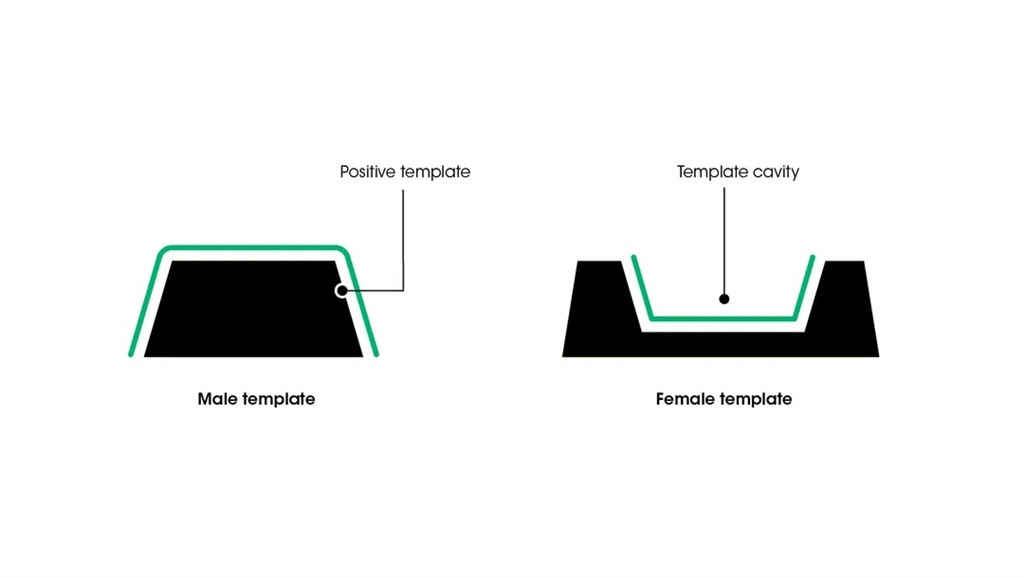

In vacuum forming, male templates are the most common . The materials used are usually thinner, and the level of detail expected in applications such as packaging is not high.

In pressure forming, the master mold is the most common type of mold used . It is typically used to create molds or parts with high-level details, textures, or other aesthetic appeal.

【 Application Scope 】

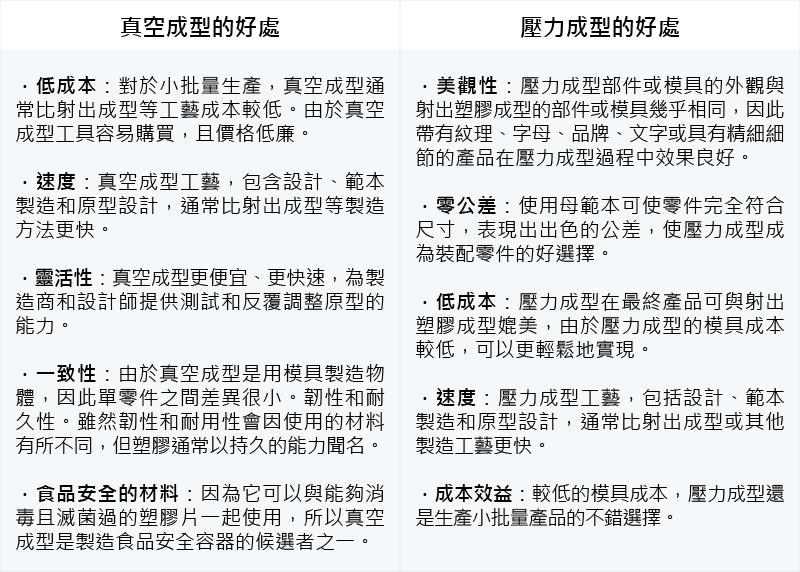

Comparison of the advantages of the two technologies

Mayku 3D Molding Machine

Mayku FormBox : Vacuum 3D Molding Machine

The Mayku FormBox is a desktop vacuum-powered 3D molding machine, part of the Mayku 3D molding machine series. 3D models are powered by technologies such as thermoforming and are as easy to use as desktop 3D printers.

Mayku FormBox is compatible with a variety of materials, including flexible and resin-resistant materials. A 1000W ceramic heater is used to heat a plastic sheet that can be replicated onto a mold. Once the plastic sheet is heated and placed on the mold, air is expelled to make the heated plastic sheet conform to the details of the mold, tool, or object.

Mayku Multiplier : Compression Molding Machine

The Mayku Multiplier is a desktop 3D molding machine that uses industrial pressure molding technology. Compatible with a variety of plastic types and thicknesses, it can produce highly detailed final parts and molds. When filled with compressed air, the multiplier's dome is pressurized to four atmospheres. This pressure forces the air into the heated plastic sheet, making it fit more closely to every crevice of the mold and enabling the capture of details smaller than 1 micrometer, such as EVA.

Did you enjoy this sharing session? You can choose the right 3D molding machine based on your needs! 3D printing offers more than just 3D printing ; contact us now to learn more about vacuum forming applications.

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References