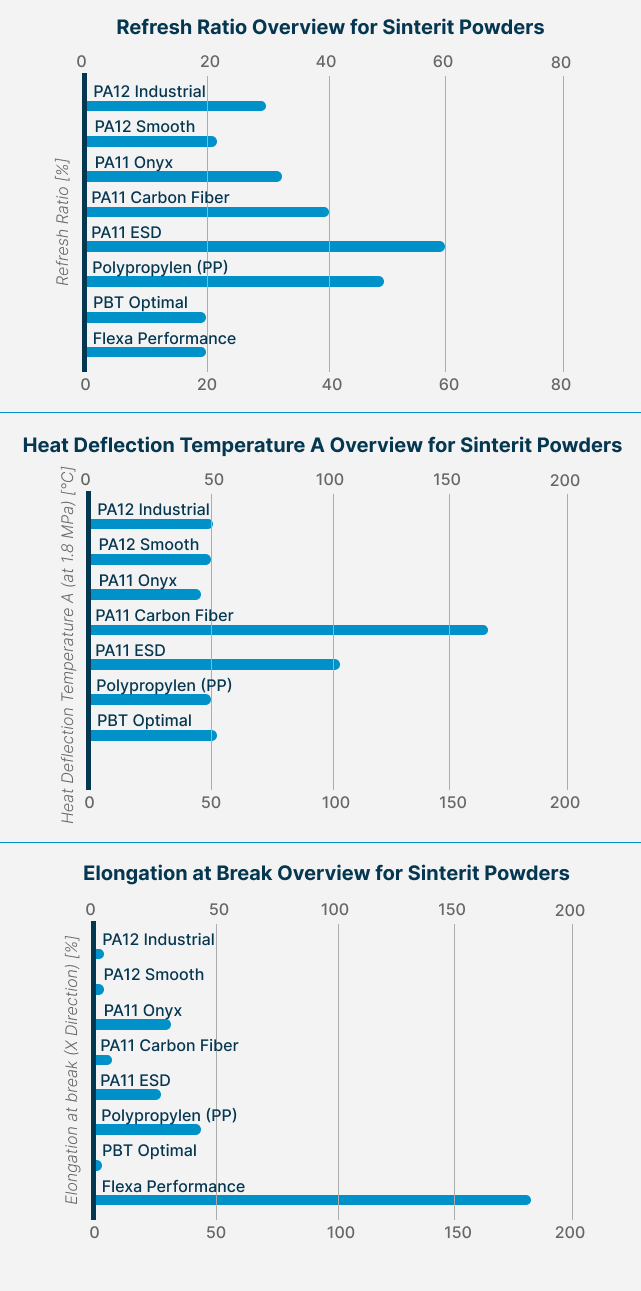

When selecting powder materials for SLS (Selective Laser Sintering), understanding the mechanical and thermal properties of each material is crucial. The five parameters presented in this comparison—tensile strength, flexural strength, elongation at break, heat deflection temperature (HDT), and refresh rate—have been carefully chosen to reflect the properties that have the greatest impact on the SLS process.

Evaluate the suitability of powders for various applications. These five parameters provide a balanced perspective on mechanical properties, thermal resistance, and economic efficiency—key factors for engineers, designers, and production managers to select the right material for specific needs.

| Powder powder | Tensile Strength Tensile strength (X) [MPa] |

Flexural Strength Bending strength (X) [MPa] |

Elongation at Break Elongation at break (X) [%] |

Heat Deflection Temp A Heat distortion temperature A (1.8MPa) [℃] |

Refresh Ratio Refresh rate [%] |

|---|---|---|---|---|---|

|

PA12 Industrial |

47.61 | 62.31 | 5.86 | 51 | 30 |

|

PA12 Smooth |

38.44 | 49.18 | 4.55 | 50 | twenty two |

|

PA11 Onyx |

55.00 | 54.20 | 31.60 | 47 | 33 |

|

PA11 Carbon Fiber |

65.93 | 87.35 | 8.23 | 167 | 40 |

|

PA11 ESD |

50.00 | 56.00 | 28.00 | 103 | 60 |

|

Polypropylen (PP) |

19:30 | 25.60 | 44.40 | 50 | 50 |

|

PBT Optimal |

49.04 | 52.08 | 2.56 | 52 | 20 |

|

Flexa Performance |

7.99 | - | 182.63 | - | 20 |

Key Technical Parameters Explanation

1. Tensile Strength <br>This indicates the maximum stress a material can withstand when stretched before breaking. For the user, this reflects the tensile or tensile strength of the printed part—crucial for snap-fit components, housings, and structural elements.

2. Bending Strength <br>Measures the bending force a material can withstand before failure. This is important for slender or beam-like components that may bend or buckle during use.

3. Elongation at break <br>This indicates the degree to which a material can be stretched before breaking—a measure of flexibility or ductility. A high value = flexible and impact-resistant parts. A low value = stiff and brittle.

4. Heat distortion temperature A (HDT A)

This indicates the temperature at which a material begins to deform under pressure. High heat deflection temperature (HDT) indicates that the part is suitable for high-temperature environments, such as engine compartments or electronic housings.

5. Refresh Rate <br>Describes how much fresh powder needs to be added to the old material to maintain print quality. The lower the value, the lower the powder usage cost and the higher the sustainability.

![]() Regardless of the challenges, Sinterit powder, combined with Sinterit Studio software, provides customized solutions for precise, professional-grade SLS printing.

Regardless of the challenges, Sinterit powder, combined with Sinterit Studio software, provides customized solutions for precise, professional-grade SLS printing.

Material highlights listed by key performance parameters

· tensile strength

PA11 Carbon Fiber (65.93 MPa) ➡ Has the highest tensile strength - ideal for structural load-bearing components.

· Bending strength

PA11 Carbon Fiber (87.35 MPa) ➡ Offers excellent bending resistance - ideal for components such as brackets, frames, and housings.

• Elongation at break

Flexa Performance (182.63%) ➡ Excellent flexibility – recommended for hinges, seals, and damping components. PBT Optimal (2.56%), on the other hand, ➡ Superior stiffness, suitable for all applications requiring high stiffness.

• Heat distortion temperature A (HDT A)

PA11 Carbon Fiber (167°C) ➡ High temperature resistance - Ideal for technical or automotive applications.

• Reorganization rate

PBT Best (20%) ➡ Powder reuse is most cost-effective – ideal for economical prototyping workflows.

To order Sinterit products, please click the "Contact Us" button below.

👉Learn more about Sinterit products

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | T hreads

References