We keep saying we need to transform, that we must transform, but we face various challenges:

1. Customers require small quantities of diverse, highly customized components.

2. The response time to customer needs is too short.

3. The geometry of the component is difficult to machine, and traditional machining methods cannot complete it.

4. Geometric variations or complexities lead to excessively high mold costs (time cost/manufacturing cost).

5. The need for lightweight design without compromising product strength/function.

Processing time is thus endlessly consumed and endlessly repeated...

HP Jet Fusion 3D printing solutions are fundamentally reshaping design and manufacturing processes. From accelerating design cycles to print functional parts, to leveraging the quality of repeatable parts to execute efficient mass production.

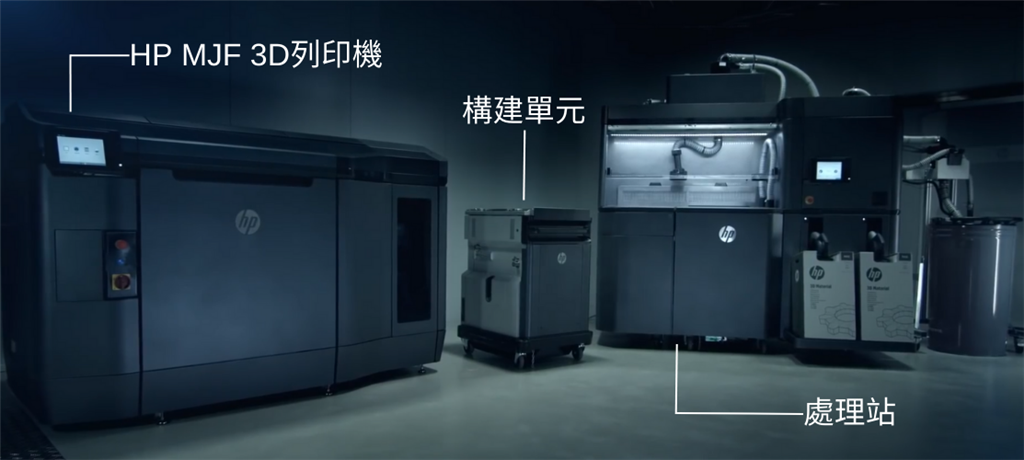

Multi-Jet Fusion (MJF) is an additive manufacturing technology designed by HP. MJF belongs to the powder bed fusion family of technologies, which also includes selective laser powder sintering (SLS) and powder inkjet technology. It can produce prototypes with detailed functions and low- to medium-volume production. Multi-Jet Fusion printers manufacture relatively robust, highly detailed plastic parts with near-mechanical isotropic properties.

How does the MJF 3D printer work?

HP uses Multijet Fusion 3D printing technology, and the molding process is as follows:

1. The material is loaded into the 3D printer, and the printing carriage (Priny Carriage) starts moving according to the programmed digital instructions and slides across the powder bed to begin production.

2. Inkjet arrays selectively apply melt additives and refiners to a powder bed, then fuse them into a robust layer that conforms to the part geometry using thermal energy.

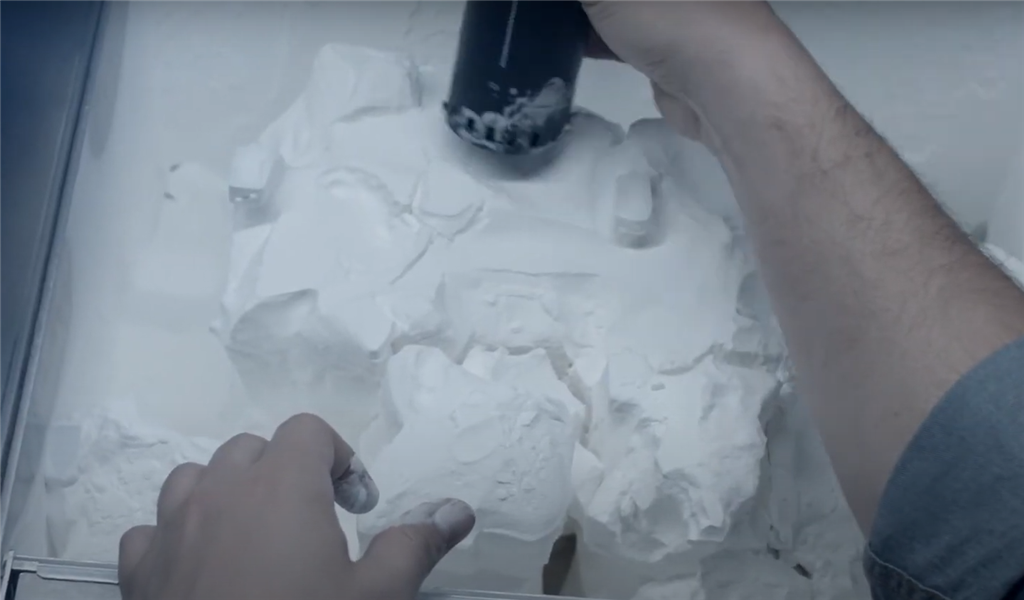

3. The powder is dispensed by the material recoating unit, and this process is repeated layer by layer until construction is complete.

HP's Multi-Jet Fusion Technology Principle

➊ Spreading and molding powder

HP’s proprietary architecture enables it to print 30 million drops per second on every inch of the bed, achieving high precision and dimensional accuracy.

➋ Fusing agent

An auxiliary agent is coated onto the material layer to fuse the particles together.

➌ Spraying detailing agent

Apply a refining agent to modify the fusion and create a richly detailed and smooth surface.

➍ Apply energy to the forming area to melt the powder.

This area is exposed to energy, and the reaction between the formulation and the material causes the materials to selectively fuse together to form a part.

Repeat the process from ➊ to ➍ until all slices are processed, noting that the areas sprayed with the refining agent are not melted.

Advantages of Multi-Jet Fusion in 3D Printing

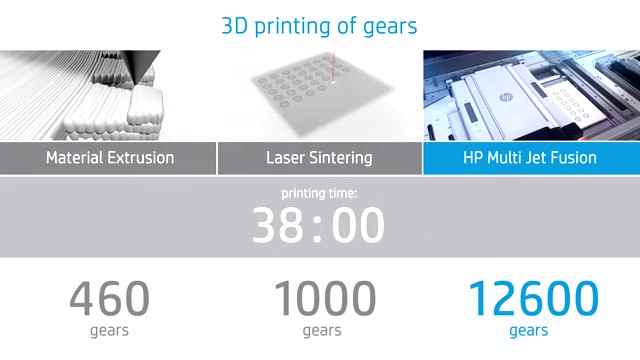

Fast printing speed

MJF is a rapid additive manufacturing technology, the biggest highlight of HP 3D printers, surpassing conventional technologies by 10 times . The image below shows that, taking the same 38 hours, the extrusion technology (FDM) on the left printed 460 units; the SLS technology in the middle was slightly better, printing 1000 units; but the Multi-Jet Fusion technology on the far right surpassed the previous two, printing a whopping 12600 units!! This proves that HP's 3D printers can meet customers' short-term needs.

Comparison of FDM, SLS, and MJF printing speeds

tough and resilient

The following video provides a small demonstration of HP's amazing 3D printing quality. The team printed an oval-shaped part in just 30 minutes, and this part, weighing only about 113 grams, could support a 5-ton car!!!

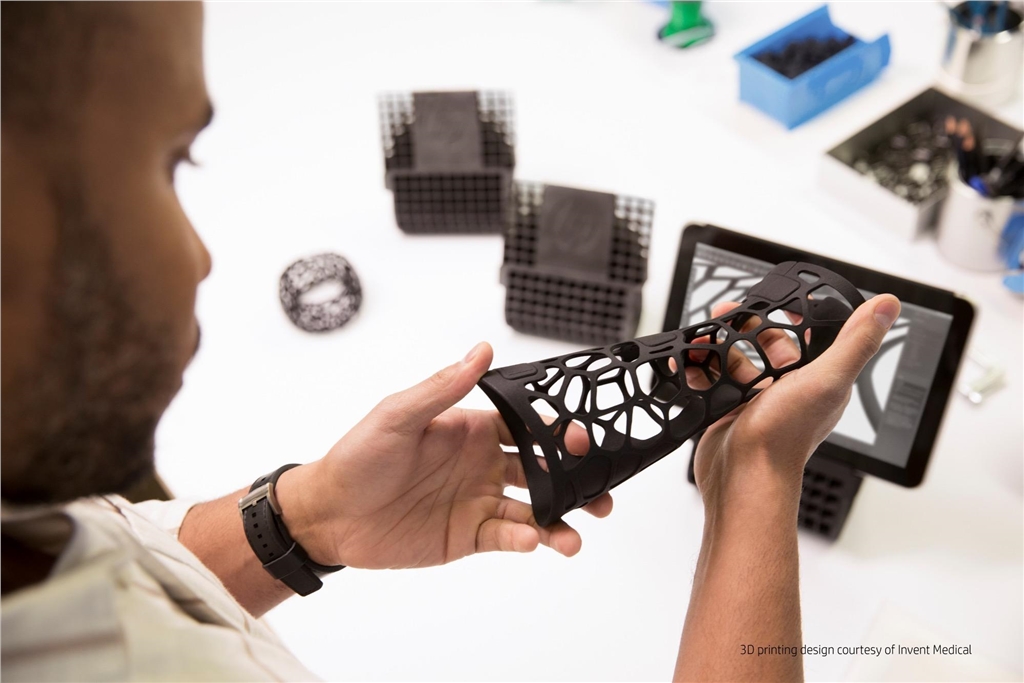

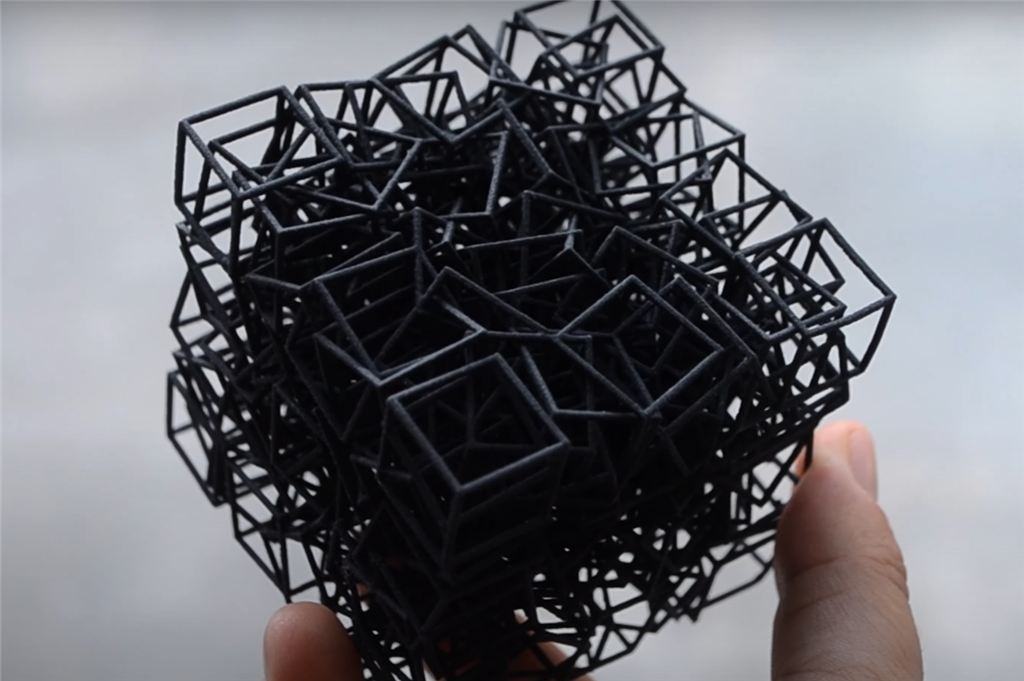

Design freedom

Because MJF belongs to the powder bed fusion technology family, it does not require a support structure, as the powder provides support during the printing process. This allows for greater design freedom and leaves no noticeable removal marks. Therefore, multi-jet fusion is well-suited for complex geometries. (Note that large flat areas should be avoided, as MJF does not handle these areas well. If large flat areas cannot be avoided, consider adding a lattice structure.)

High-precision printing

MJF can 3D print small features while retaining detail, with a minimum feature size of 0.02 inches or 0.5 millimeters. MJF can print 80 micrometers per layer.

Application areas of HP MJF 3D printers

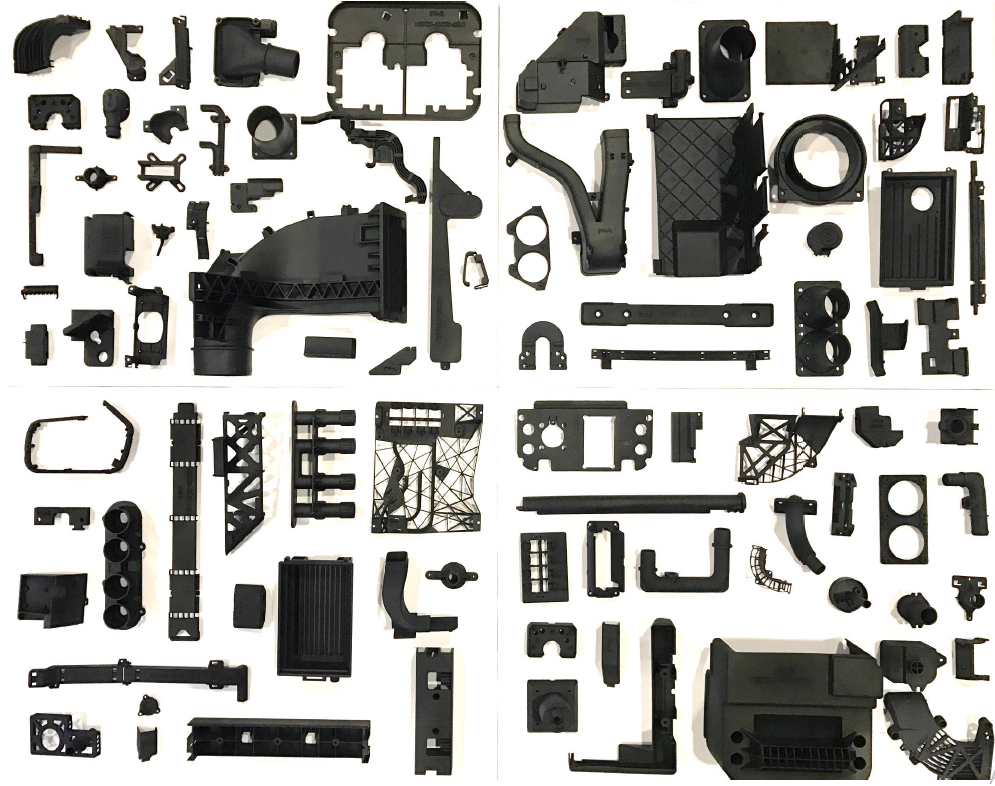

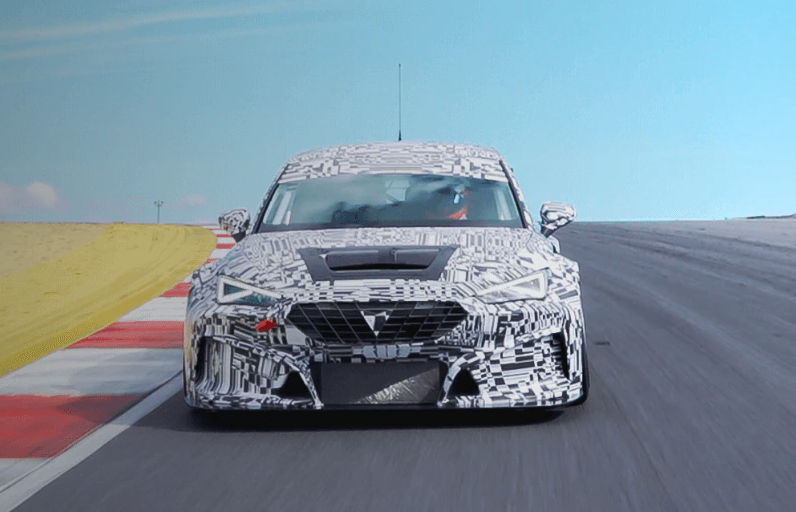

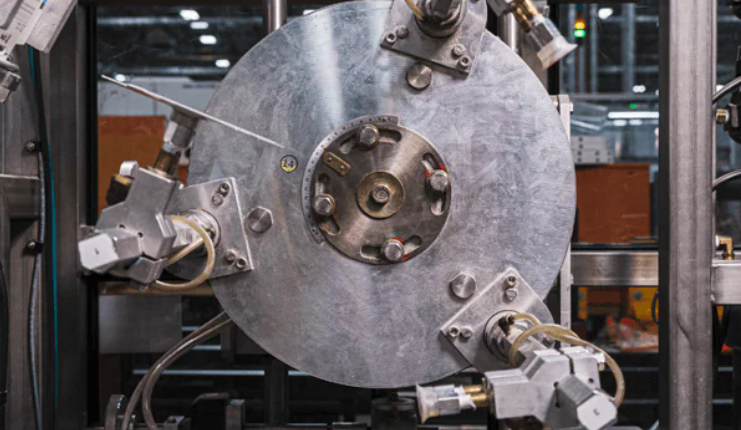

Machinery and Transportation

• Battery cooling system

• New car prototype production • Interior components (1 million BMW window rails)

• New energy electric vehicles • Drones

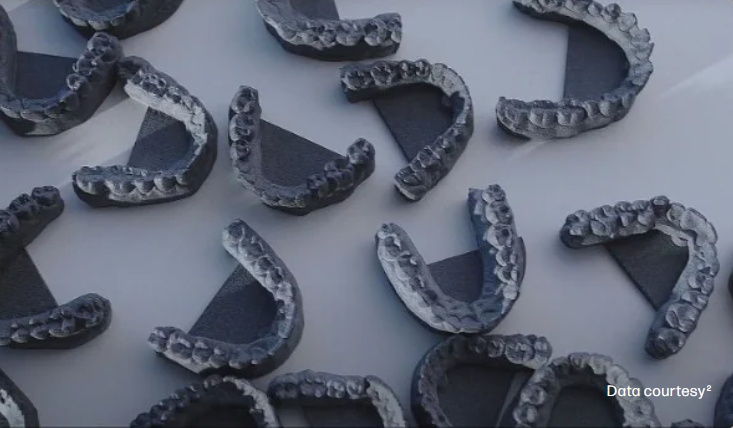

healthcare

• Invisible braces offer a concealed aesthetic, Smile Direct

• Prosthetics, assistive devices • Orthopedic insoles, shoe soles • Infant head shaping braces

Industry and Services

• Fixtures, jigs • Robotic arms • Rapid prototyping • Hardware tools • CNC machining supplements • Exoskeletons

Consumer products and electronic devices

• Custom-made eyewear • Designer home decor, lighting • Orthopedic shoes • Sporting goods

-Contact Us-

Find more information on filaments and 3D printers ! Make an informed choice to meet your needs!

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook: https://www.facebook.com/3dmart.com.hk/

Instagram: https://www.instagram.com/3dmart

LinkedIn: https://www.linkedin.com/company/3dmart/

References