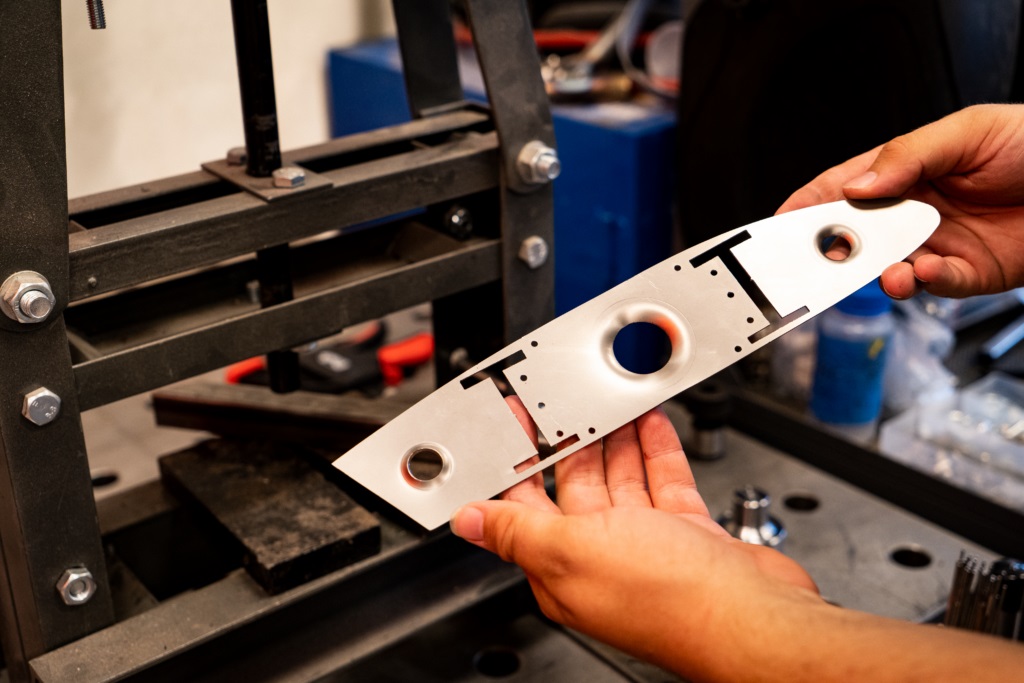

Waterjet Cutting: Waterjet cutting machines create high-precision parts from titanium.

Form follows function

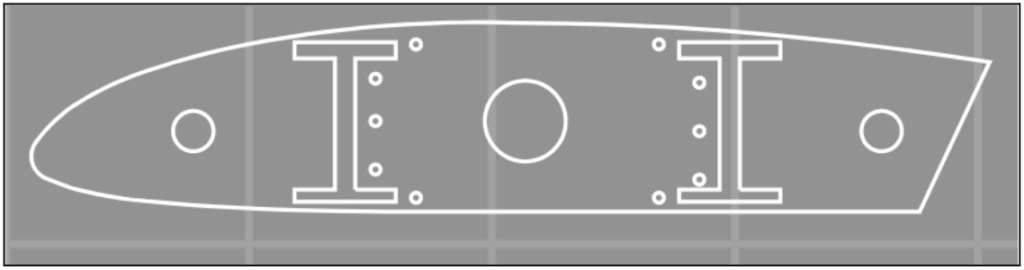

Waterjet cutting can create highly precise parts that function as functional components. What factors are related to producing precise parts? How can we push the limits of waterjet cutting for high-precision cutting? By understanding the waterjet cutting process firsthand, we can consistently achieve precise parts. This article uses the famous Clark Y-wing as an example.

Waterjet cutting can create highly precise parts that function as functional components. What factors are related to producing precise parts? How can we push the limits of waterjet cutting for high-precision cutting? By understanding the waterjet cutting process firsthand, we can consistently achieve precise parts. This article uses the famous Clark Y-wing as an example.

The shape and size of the ribs will vary depending on the intended use, but a common factor is always the precision of the ribs. Because these parts will withstand great forces and need to be as lightweight as possible, it is crucial to manufacture the features correctly to prevent component failure.

Precision cutting

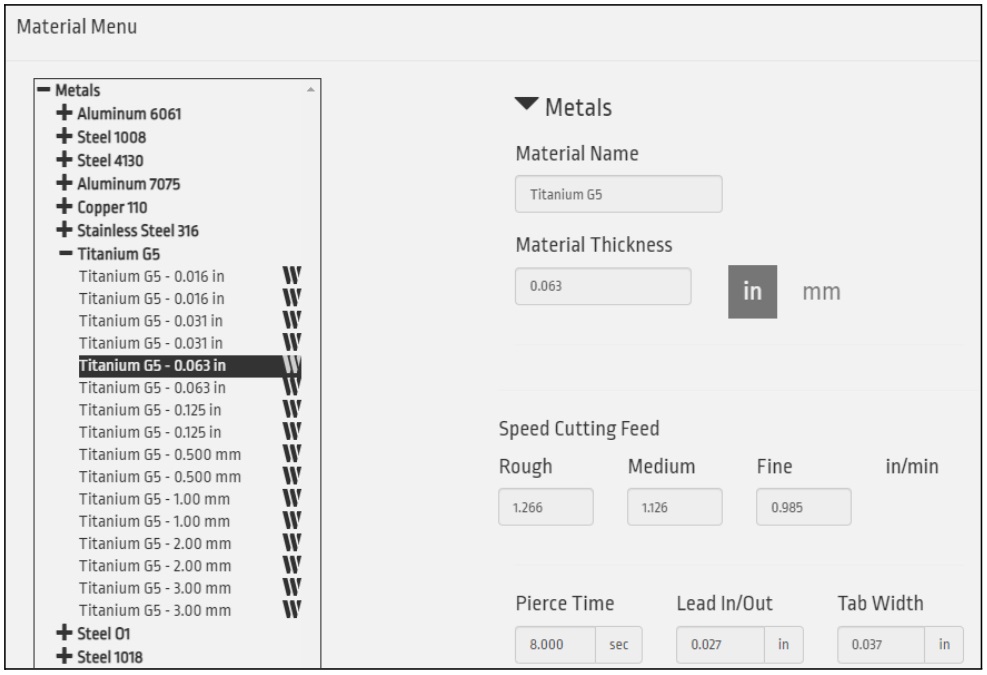

A key factor in waterjet cutting is the physical mixing of water and abrasive materials, which is a constant in cutting parts. However, the cutting method of a waterjet cutter can vary depending on the material, thickness, and selected cutting speed. All these factors ultimately stem from a simple question: what material to use? Titanium was chosen this time because of its light weight and difficulty in machining.

Precision cutting

A key factor in waterjet cutting is the physical mixing of water and abrasive materials, which is a constant in cutting parts. However, the cutting method of a waterjet cutter can vary depending on the material, thickness, and selected cutting speed. All these factors ultimately stem from a simple question: what material to use? Titanium was chosen this time because of its light weight and difficulty in machining.

The first step is to upload the DXF file to the WAM software, position it on the cutting bed, and select the desired titanium thickness. WAM can use preset cutting material parameters from its material database, such as cutting speed, label size, and piercing time, as shown below.

Detailed settings for the cutting path

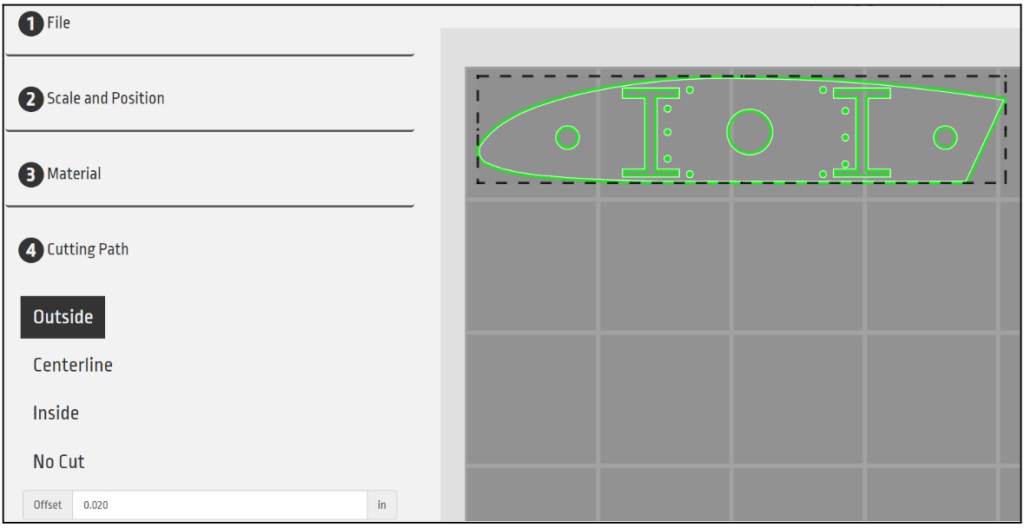

After placing the part and selecting the material, choose the cut path that best suits the part. There are three options: Outer, Centerline, and Inner. Each option affects the final dimensions of the part. Outer cut offsets the waterjet flow (cut) to one side of the white design line, providing the most accurate cut profile for the designed dimensions.

The other two options, centerline and inside, shift the jet flow to the center and inside of the design white line, respectively. This will result in the cut part being smaller than the design dimensions, meaning the best choice for accuracy is the external cutting path.

The next variable to consider is the offset. The offset refers to the width of the cut, which is the width of the nozzle. WAM automatically sets it to 0.019 inches, which is the nozzle size. Long-term use of the WAZER can cause the nozzle opening to increase, so when the actual width is measured on the WAZER , the nozzle still appears to be at its original offset size.

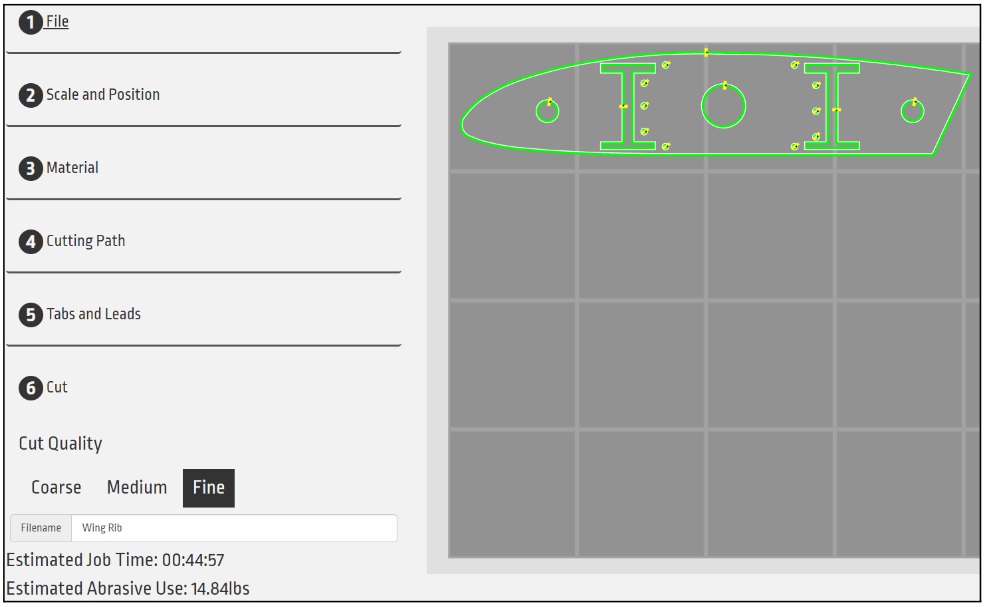

The last option in WAM that helps achieve higher precision is cut quality. The three options range from coarse to fine cut quality. A coarse cut is faster but of lower quality, while a fine cut is slower but produces higher quality. The goal here is high precision, so the fine setting is selected.

The next variable to consider is the offset. The offset refers to the width of the cut, which is the width of the nozzle. WAM automatically sets it to 0.019 inches, which is the nozzle size. Long-term use of the WAZER can cause the nozzle opening to increase, so when the actual width is measured on the WAZER , the nozzle still appears to be at its original offset size.

The last option in WAM that helps achieve higher precision is cut quality. The three options range from coarse to fine cut quality. A coarse cut is faster but of lower quality, while a fine cut is slower but produces higher quality. The goal here is high precision, so the fine setting is selected.

Create parts

After setting everything up and moving the WAZER cutting head to the appropriate position, it was possible to cut across the entire sheet of material. After cutting, several points on the part were measured, and the results were compared with the design dimensions. Waterjet cutting of titanium yielded surprisingly good results, requiring neither expensive tools nor highly skilled technicians.

After setting everything up and moving the WAZER cutting head to the appropriate position, it was possible to cut across the entire sheet of material. After cutting, several points on the part were measured, and the results were compared with the design dimensions. Waterjet cutting of titanium yielded surprisingly good results, requiring neither expensive tools nor highly skilled technicians.

Additionally, a post-processing step involves using a dimple mold to create the classic curved circular cutouts found on many aircraft parts. This helps increase the rigidity of the part without adding weight. The project's testing results were quite good, and it is believed that this process will have many real-world applications.

Did you enjoy this sharing? 3D printers offer more than just 3D printing . Contact us now to learn more about our 3D printers and 3D scanners .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References