[Pressure Molding] Custom racing helmets made on a multiplier

In motorsports, the design and manufacture of helmets are crucial, as they must provide safety protection while also meeting the drivers' needs for personalization and performance.

Recently, " Multiplier " technology has been applied to the manufacture of custom racing helmets, providing race car drivers with new options.

In the fast-paced world of NASCAR, drivers spend hours behind the wheel, battling not only rivals but also the sweltering heat.

One of the most effective ways for drivers to combat the heat is to use a helmet air system, which delivers a steady airflow directly into the helmet.

Proforming LLC, founded by Chris Hladik in North Carolina, develops customized airflow systems that keep drivers cool, altering racing conditions through its innovative helmet air systems.

Founder Chris Hladik started with vacuum forming and improved the process to a very high level, but quality issues still existed.

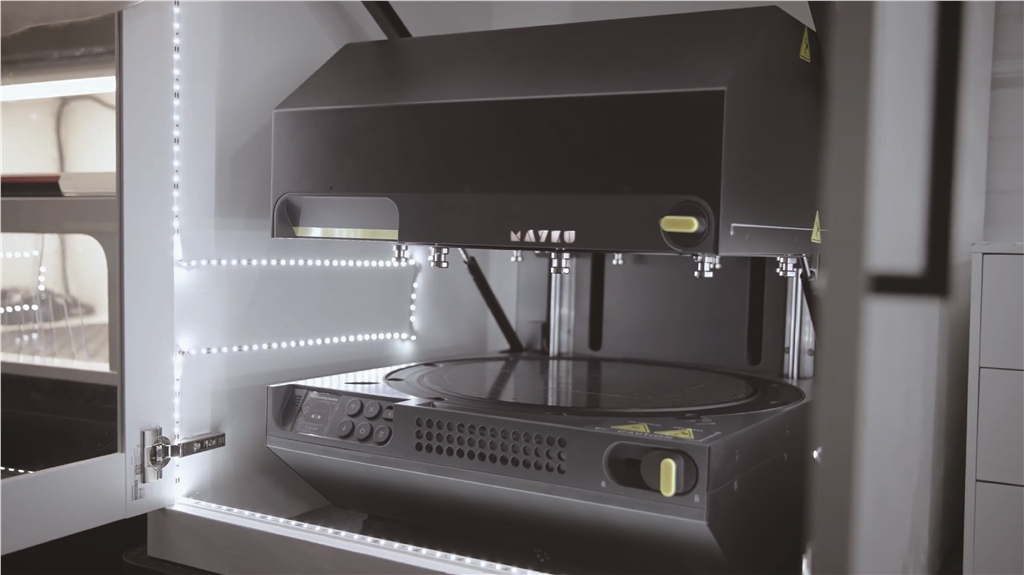

While studying pressure molding, he discovered the Mayku Multiplier .

Understanding how it works and how it pairs perfectly with the right materials was truly eye-opening. He was all smiles for days after receiving it and testing it thoroughly.

They carefully designed the cooling channels using a multiplier.

Customized air ducts deliver cooling air directly to the driver's helmet, keeping the driver in optimal condition even when the cockpit temperature soars to 140°F.

In addition, these parts are capable of withstanding impacts from debris traveling at speeds exceeding 200 miles per hour.

Furthermore, thanks to the assistance of equipment, the turnaround time for customized products from concept to delivery has become quite fast, and the quality can be kept consistent throughout the manufacturing process.

Proforming's designs have been used in renowned racing series such as the Cup, Xfinity, IndyCar, DIRTcar, and Sprint Car.

Their system uses dedicated air conditioning or ambient air to help regulate the driver's body temperature and improve comfort and performance on the track.

In high-speed racing events such as NASCAR, drivers wear helmets for extended periods, requiring strict standards for comfort and fit.

Traditional helmet manufacturing methods may not be able to meet the personalized needs of each racing driver, but the introduction of "Multiplier" technology improves the comfort and safety of helmets through precise customized manufacturing.

Want to learn more about Mayku products? Click "Contact Us" below!

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram