[3D Printing] BAE Systems uses 3D printing technology to create a new Storm Fighter demo unit.

British Aerospace company BAE Systems is producing a supersonic demonstrator to support the Global Combat in Air Program (GCAP).

This manned aircraft prototype will be used to test a range of new technologies, including stealth compatibility features.

These tests will be the first combat air demonstrator in the UK in 40 years and will support the development of the next-generation Tempest fighter jet.

Launched in 2022, GCAP combines Japan's foreign exchange program with the Team Tempest program from the UK and Italy. The company is working towards producing a sixth-generation supersonic fighter jet by 2035.

This British defense company is using additive manufacturing technology to produce key structural components for the demonstrator aircraft, most of which are manufactured in the UK.

Paul Wilde, head of BAE Systems Tempest, said, "Some parts on aircraft cannot be manufactured by any other means except through the use of a laminated process."

It is already known that 3D printing plays a key role in the development and manufacturing of the Tempest fighter jet. BAE previously claimed that 30% of the Tempest's parts would be 3D printed .

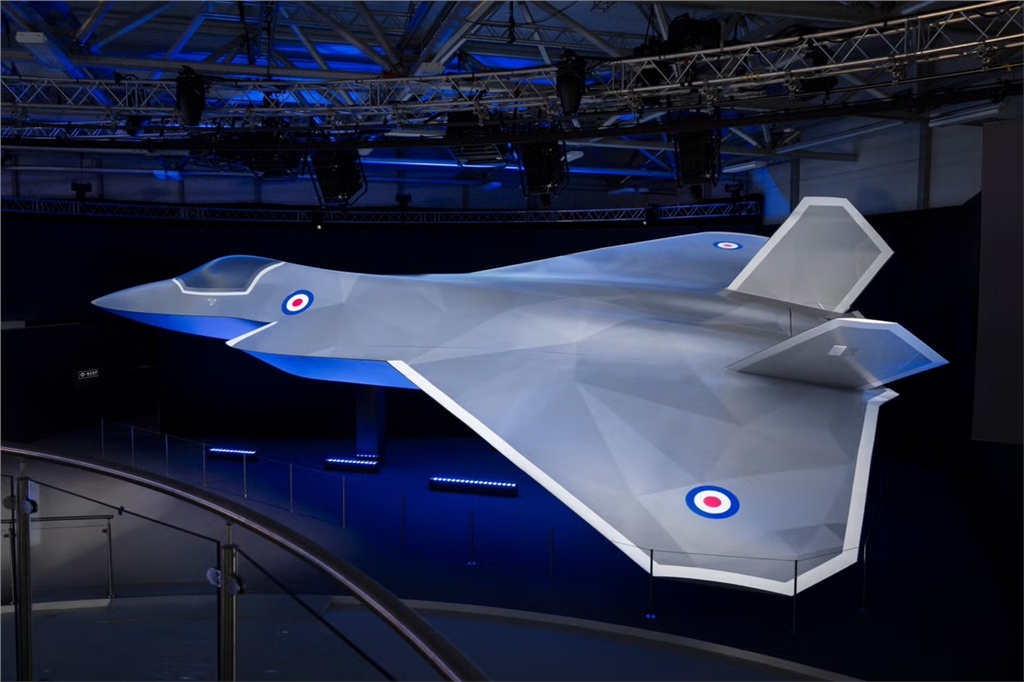

The company also unveiled a new design for the GCAP fighter jet and showcased a life-size demonstrator at the Farnborough International Air Show. The model features new design elements, including a larger wingspan than previous concepts. This is reportedly expected to improve the aircraft's aerodynamic performance.

BAE 3D Printing of Sixth Generation Fighter Jets

BAE officials reported that the aircraft passed the Critical Design Review (CDR) in May. Half of the aircraft prototype's weight has now been manufactured or assembled, while the forward center, aft, and wing sections are under construction.

Structural components are manufactured using a multilayer manufacturing process, including industrial 3D printing and hot isostatic pressing (HIP).

HIP (High-Intensity Printed Process) presses titanium powder together under high temperature and pressure to produce metal parts. This minimizes waste and significantly reduces lead times associated with forgings. According to BAE, project engineers also utilize DfAM (Design for Building Achievement) design when producing structural parts.

The time saved by additive manufacturing could play a key role in shortening the development time of the Tempest, which is expected to be delivered just 12 years after the signing of the trilateral agreement. That's roughly half the time it took to produce the previous generation Eurofighter Typhoon.

According to the Financial Times, BAE is 3D printing molds to manufacture carbon fiber parts for Tempest. These "mold tools" are traditionally made of steel and typically take 26 weeks to produce using conventional methods. Using additive manufacturing, BAE can create a complete tool in just three weeks.

By creating "Tempest," GCAP aims to produce one of the world's most advanced, interoperable, adaptable, and connected fighter jets. It will integrate intelligent weapon systems, a software-driven interactive cockpit, and integrated sensors. The next-generation radar is reportedly expected to provide 10,000 times more data than current systems.

According to BAE, the Tempest will also be the first British-made tactical fighter to feature an integrated payload bay since the Blackburn Corsair in 1958. This integrated avionics flight platform design architecture enhances its adaptability.

BAE's demonstrator aircraft will provide evidence for key technologies, methods, and tools to be used in future combat air systems.

In Walton, Lancashire, test pilots from BAE Systems, Rolls-Royce, and the Royal Air Force (RAF) have already spent over 215 hours in the demonstrator's flight simulator. While the Tempest Demonstration Program is a UK sovereign project, the lessons learned will be fed back into the trilateral GCAP program.

Japan has already test-flown its future fighter demonstrator, the Mitsubishi X-2, which made its maiden flight in 2016.

Fighter jets that support 3D printing

By employing additive manufacturing in fighter jet production, Western countries are seeking to gain an advantage in an increasingly challenging geopolitical environment. However, Russia and China are also using 3D printing to enhance their military aircraft production capabilities.

The Russian military previously used 3D printing to upgrade MiG-31 jet aircraft. These upgrades, carried out by UEC-Perm Motors and UEC-Star, a subsidiary of the state-owned Rostec Group, significantly improved the interceptor's engine performance.

Engineers from UEC-Perm Motors and UEC-Star have reportedly 3D-printed parts for the MiG D-30F6 engine, enabling it to reach a "new level of quality." The additional research and development is reportedly capable of producing a "domestic engine" that offers "better performance." This comes after Rostec received permission from the Russian Ministry of Industry and Trade to mass-produce 3D-printed aerospace parts. Prior to this, state-supported additive manufacturing of aircraft engines had been successfully tested.

According to reports, Shenyang Aircraft Corporation (SAC) in China has widely adopted 3D printing technology in fighter jet production. It is understood that additive manufacturing technology makes aircraft parts and components lighter and more durable.

In 2022, Dr. Li Xiaodan from the Process Research Institute of Shenyang Aircraft Corporation told CCTV, "3D printed parts were widely used on the newly developed aircraft that recently made its maiden flight." He added, "We are applying 3D printing technology on a large scale to aircraft at the engineering level, and we are in a world-leading position."

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram