[3D Scanning Application] AESUB scanning powder spraying requires no cleaning, and is used in large automobiles!

Robotic arms for 3D scanning : Easily scan car chassis! Automatic evaporation eliminates the need for cleaning. AESUB BLUE / Orange / Green series scanning powder spraying is used for optical measurement, automotive dashboard frames, and car chassis. See three applications for ultra-large-area 3D scanning :

1. Automated optical measurement

MQS (Measurement Service Provider) is a German measurement service provider that has been providing a wide range of 3D measurement and automation services through 3D scanning since its inception. For delicate and structurally complex industrial parts, the complex appearance conditions increase the difficulty of measurement, but it is also an indispensable step in the engineering process.However, automotive parts such as headlights, chassis, and dashboards are made of transparent materials that reflect light, which can affect the results of 3D scanning. These materials cannot be successfully developed during 3D scanning . The MQS team used Universal Robots robotic arms to spray AESUB Green scanning powder/developer onto the parts. This leaves a layer of white powder on the surface of the object. Then, a 3D scanner is used for reverse engineering. The powder will automatically evaporate after a few hours.

2. Extensive scan of the vehicle chassis.

Renowned automotive brand BMW uses AESUB Green scanning powder coating paired with a dedicated scanning spray gun to quickly paint the undercarriage structure of its vehicles in the shortest possible time. Then, SHINING 3D scans the chassis. Painting large, complex surfaces by hand would be extremely time-consuming and labor-intensive. With the assistance of the AESUB dedicated spray gun , efficiency is significantly improved, ensuring complete and high-precision scanning results. ( Click to watch: [Real-world Test Video] AESUB Powder Coating, the Ultimate Showdown! )AESUB's ability to automatically evaporate its scanning powder makes it suitable not only for scanning complex objects, but also for electronic components and metal objects. After 3D scanning , there is no need to clean it with water or cloth. Even the powder particles in the gaps of the structure will disappear automatically. The object can be used normally without water or rubbing.

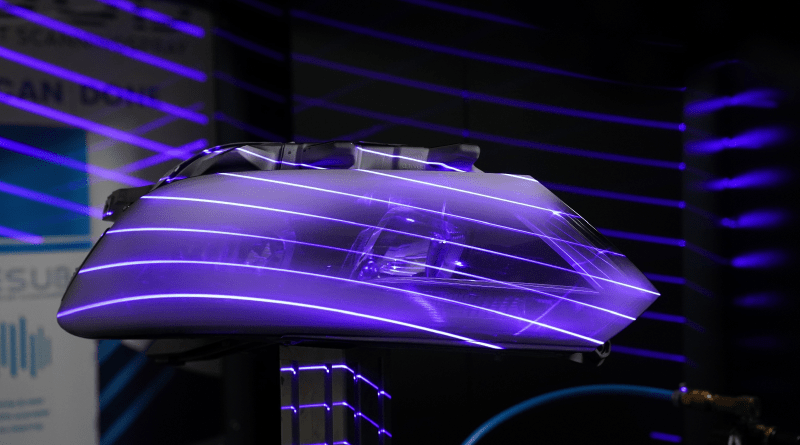

3. 3D printed dashboard frame

BMW combined 3D scanning and 3D printing to create the dashboard frame. AESUB Orange was used for scanning and powder coating, and a scanning positioning sticker was applied to the outside of the dashboard to increase scanning accuracy. Then, a SHINING 3D scanner was used to capture the entire frame into a digital file, and finally, it was 3D printed to perfectly match the size of the dashboard.As seen in the video, the powder coating on the dashboard frame disappears automatically over time, without damaging the functionality of the car parts, and can also produce 1:1 scale, high-precision 3D images.

Did you enjoy this sharing session? AESUB scanning powder coating assists various fields in meeting their 3D scanning needs. Its self-evaporating and cleaning-free characteristics further expand its application scope. Combined with other technologies, it can bring more convenient operations and create higher efficiency for businesses. SanDiMa offers more than just 3D printing ; contact us now to learn more about AESUB scanning powder coating .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart