[3D Printing] 3DMart's amazing showcase at Intelligent Asia 2024: "RX-0 Unicorn Gundam"

At this year’s Intelligent Asia 2024, Sandima proudly showcased our industry-leading 3D printing creations.

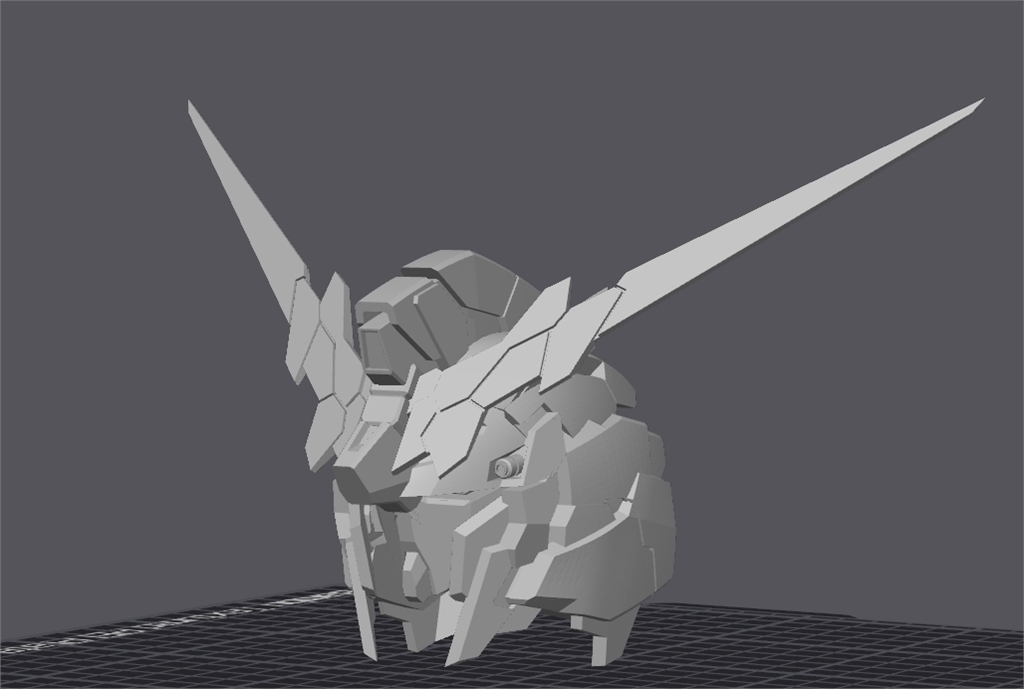

We have meticulously presented the stunning creation, "RX-0 Unicorn Steel Gundam".

This is not only a demonstration of our product's features, but also a reflection of our uncompromising commitment to detail and quality.

At this year’s Intelligent Asia 2024, Sandima proudly showcased our industry-leading 3D printing creations.

We have meticulously presented the stunning creation, "RX-0 Unicorn Steel Gundam".

This is not only a demonstration of our product's features, but also a reflection of our uncompromising commitment to detail and quality.

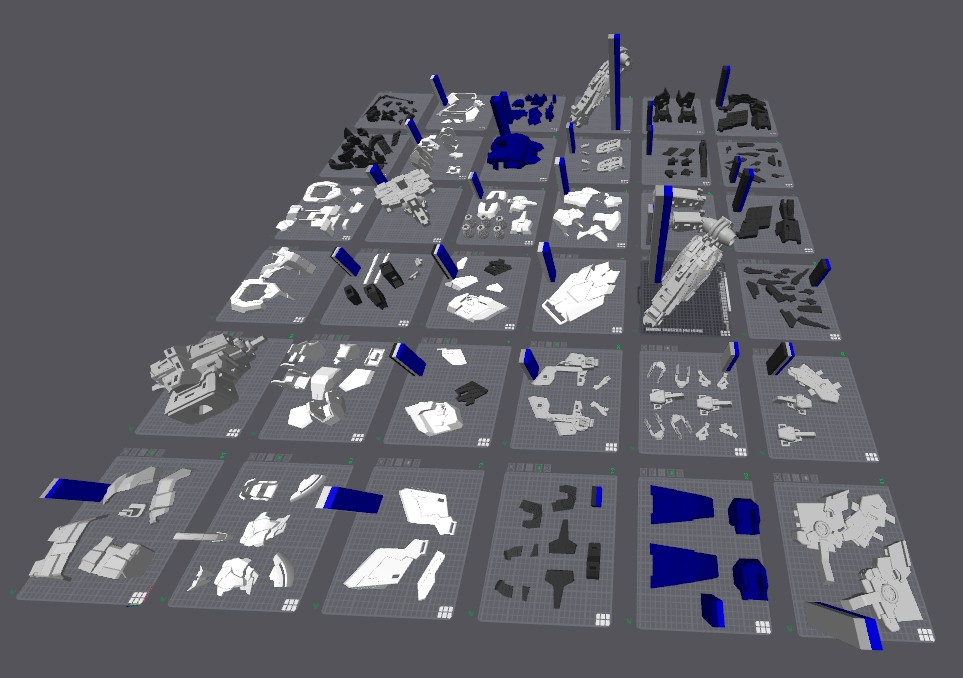

The "RX-0 Unicorn Steel" exhibit at this exhibition. This model, measuring 110x40x100CM, showcases Bambu Lab 's exceptional capabilities in both hardware and software processing. The entire production process of this exhibit utilized Bambu Lab's "Bambu Studio" software.

It is feature-rich and easy to use, with numerous optimized systems and slicing algorithms that helped us process up to 1716 parts.

In terms of hardware, considering the huge size, we used three 3D printers from Bambu Lab —the X1E, X1CC, and P1SC—each of which played an indispensable role in the printing process.

The P1SC 's out-of-the-box functionality and advanced vibration compensation technology make multicolor printing simpler and more accurate. The P1S's 20,000 mm/s² acceleration and new vibration compensation system ensure high efficiency and high quality during the printing process. Even as the most basic model among the machines used in this project, it was more than capable of handling this demanding task.

The X1CC , a versatile 3D printer suitable for everyone, boasts capabilities in printing on a variety of materials and with high precision. Its housing is made of aluminum and glass, supports a range of high-performance materials such as PC, ABS, PLA, and carbon fiber, and features an acceleration of 20,000 mm/s², enabling high-speed and efficient printing. The X1CC's AI first-layer detection and dual automatic bed leveling technology ensure perfect alignment of each layer during the printing process, avoiding any defects caused by material issues.

One of the highlights of our showcase was the X1E , demonstrating its superior industrial-grade performance. This 3D printer boasts a maximum hot-end temperature of 320°C, enabling it to handle a wider range of advanced high-performance materials, such as PPA-CF/GF, PPS, and PPS-CF. The X1E's high-performance air filtration system effectively reduces excessive odors and particles, ensuring stability and environmental friendliness during extended printing. Furthermore, its 60°C chamber heating function further enhances performance when printing on special materials, significantly reducing the risk of warping and improving material adhesion and print quality. This is particularly important for parts with sharp, pointed shapes, ensuring precise rendering of every detail.

The Future of 3D Printing: Innovation and Applications . 3D printing technology is rapidly developing, with a very broad range of future applications. The model showcased here is just one of the most basic applications. This technology can not only reduce development costs and improve production efficiency in manufacturing, but also demonstrate strong potential in fields such as medicine, aerospace, construction, and education. We believe that 3D printing will definitely become an important tool for future innovation and solutions.

As a leading promoter of 3D technology, 3D is committed to introducing the world's most advanced high-end equipment and providing professional technical support and services. We are not just a supplier, but your partner in innovation and development. We offer comprehensive services, including equipment selection, material recommendations, professional engineering training, and after-sales support, designed to help our clients realize their creative and business needs.

Sharing the key steps in the parts printing process

1. After opening the file, check the model and confirm whether the model design needs to be modified or adjusted.

2. Begin placing parts and planning the platform layout to maximize printing efficiency, and place the larger printing surfaces upwards whenever possible.

3. Install supports and select support materials.

4. Use Bambu Studio's single-disc slicing function to start slicing!

5. Once you've confirmed that the above steps are correct, you can start printing!

3. Install supports and select support materials.

4. Use Bambu Studio's single-disc slicing function to start slicing!

5. Once you've confirmed that the above steps are correct, you can start printing!

Contact us now to explore endless possibilities.

We cordially invite you to learn more about Sandima and our products and services. If you are interested in 3D printing technology or need professional technical support and advice, we are ready to assist you. Please feel free to contact us so we can explore the future together and achieve innovation and breakthroughs.

SanDiMa looks forward to collaborating with you to realize your every idea and vision. Your success is our greatest pursuit, and we will wholeheartedly provide you with the best products and services.

This project used the following Bambu Lab series cameras:

► Topzhu Bambu Lab P1S Combo 3D Printer

►Bambu Lab X1 Carbon Combo 3D Printer

► Bambu Lab X1E 3D Printer

Follow our fan page to stay up-to-date with the latest news:

https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/