[3D Printing] Advantages of PPS-CF: Heat Resistant, Flame Retardant, Corrosion Resistant, and Mechanically Responsive.

PPS-CF is a composite material made of carbon fiber reinforced polyphenylene sulfide.

Because PPS has excellent affinity, it can combine very well with carbon fiber to improve mechanical properties and heat resistance, giving PPS+CF a variety of advantageous properties.

The combination of PPS resin and carbon fiber gives PPS-CF excellent solvent resistance, corrosion resistance, heat resistance and flame retardancy.

In addition, it possesses exceptional strength, stiffness, and dimensional stability, making it a special engineering plastic that can meet the needs of unique and challenging applications.

Because PPS has excellent affinity, it can combine very well with carbon fiber to improve mechanical properties and heat resistance, giving PPS+CF a variety of advantageous properties.

The combination of PPS resin and carbon fiber gives PPS-CF excellent solvent resistance, corrosion resistance, heat resistance and flame retardancy.

In addition, it possesses exceptional strength, stiffness, and dimensional stability, making it a special engineering plastic that can meet the needs of unique and challenging applications.

With the development of science and technology and the increasing demands of industry, materials science is playing an increasingly important role in all walks of life.

Among them, PPS-CF, with its superior performance and diverse applications, has gradually become the preferred material for many engineers and designers.

This article will use Bambu Lab 's PPS-CF as an example to help you understand its features and why it is widely recommended.

Heat resistance and flame retardancy

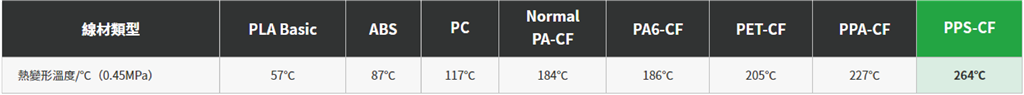

PPS-CF has a heat distortion temperature of up to 264℃ at 0.45MPa and can work continuously at temperatures exceeding 200℃.

PPS-CF has a heat distortion temperature of up to 264℃ at 0.45MPa and can work continuously at temperatures exceeding 200℃.

This is significantly better than ordinary PA-CF materials with maximum temperatures of approximately 190°C and 120°C.

Its superior heat resistance ensures excellent creep resistance, making PPS-CF an ideal choice for demanding industrial environments and applications.

Its superior heat resistance ensures excellent creep resistance, making PPS-CF an ideal choice for demanding industrial environments and applications.

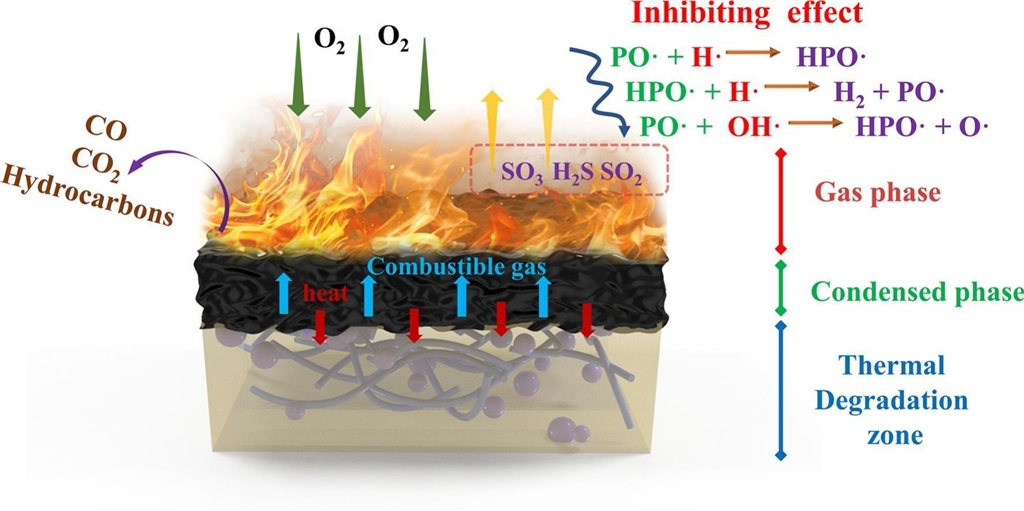

PPS-CF achieves a UL-94 V-0 flame retardant rating, providing superior safety and reliability for critical applications such as electronics and automotive parts.

Even in the harshest environments, PPS-CF provides lasting durability and peace of mind.

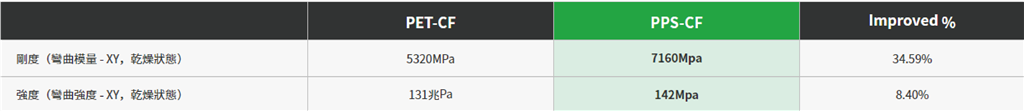

Excellent mechanical properties

PPS-CF combines the stiffness of PPS polymers with the reinforcing power of carbon fibers, providing superior stiffness, flexural strength, and tensile strength.

Its superior dimensional stability and anti-warping properties ensure that large prints maintain accuracy and avoid deformation during the printing process, making it ideal for high-precision applications.

Corrosion resistance and low moisture absorption

PPS-CF has excellent solvent and chemical resistance, second only to PTFE (Teflon).

At temperatures below 200°C, it is almost insoluble in any solvent and exhibits excellent resistance to acids, alkalis, and salts under normal conditions.

This makes PPS-CF an ideal choice for challenging environments where chemical stability is critical.

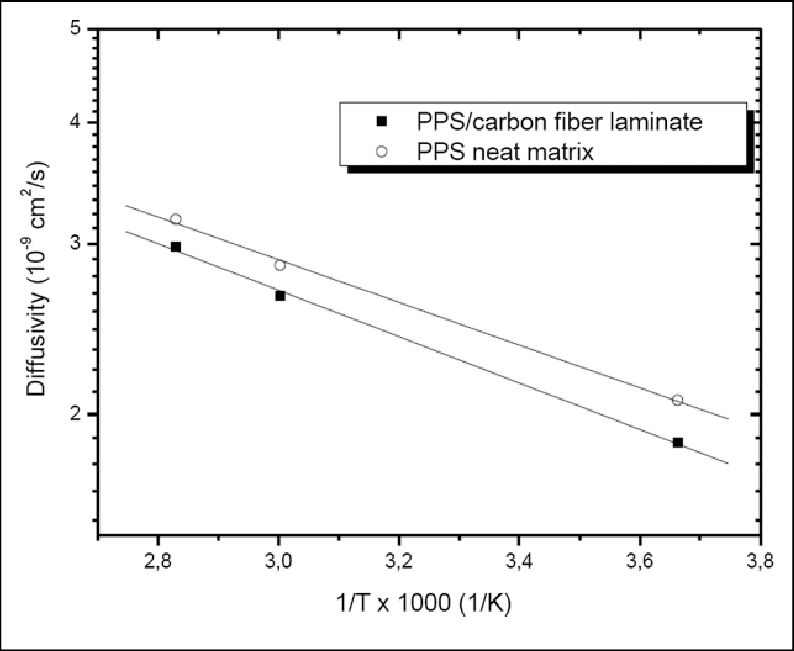

PPS-CF has an extremely low moisture absorption rate of only 0.05%, and its mechanical and thermal properties remain stable even under humid conditions.

Unlike regular PA-CF, which softens and degrades when exposed to moisture, PPS-CF retains its strength and durability, making it the best choice for applications requiring high moisture resistance.

PPS-CF has excellent solvent and chemical resistance, second only to PTFE (Teflon).

At temperatures below 200°C, it is almost insoluble in any solvent and exhibits excellent resistance to acids, alkalis, and salts under normal conditions.

This makes PPS-CF an ideal choice for challenging environments where chemical stability is critical.

PPS-CF has an extremely low moisture absorption rate of only 0.05%, and its mechanical and thermal properties remain stable even under humid conditions.

Unlike regular PA-CF, which softens and degrades when exposed to moisture, PPS-CF retains its strength and durability, making it the best choice for applications requiring high moisture resistance.

These characteristics make PPS-CF excellent for demanding technical applications, from mechanical prototypes to electronic components.

Another key feature of Bambu PPS-CF is its precision. This material performs exceptionally well under extreme conditions.

Despite its advantages, it also has its limitations. It is currently compatible with Bambu Labs' X1E printer, and its optimal printing temperature is between 280°C and 310°C.

This material is incompatible with 0.2 mm nozzles or AMS and AMS lite. It must be dried before use for optimal printing results.

Despite its advantages, it also has its limitations. It is currently compatible with Bambu Labs' X1E printer, and its optimal printing temperature is between 280°C and 310°C.

This material is incompatible with 0.2 mm nozzles or AMS and AMS lite. It must be dried before use for optimal printing results.

Want to learn more about Bambu Lab 's products? Click "Contact Us" below!

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | LinkedIn

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | LinkedIn