[3D Printing Applications] Photopolymer 3D Printing: What are the differences in performance between SLA/DLP/LCD?

Which printing method is the fastest? What are the disadvantages of photopolymerization technology? Photopolymerization technology mainly uses liquid resin as raw material. The resin is poured into a resin tank, and then a light beam from a light panel or laser UV is irradiated onto the printing platform. The resin exposed to the light gradually hardens and solidifies. Depending on the photopolymerization technology, there are three types: LCD (light panel) , SLA (laser beam) , and DLP (projection light) . Here's a summary of the photopolymerization principle, and sample details are available immediately:

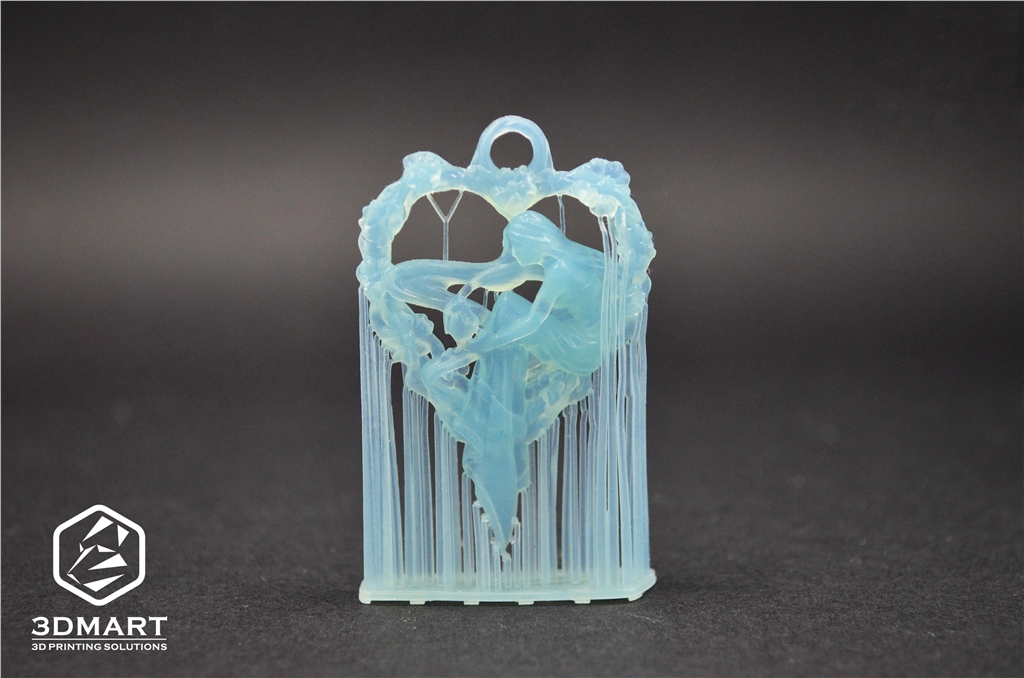

* Select a sample photo to see the production process instantly!

LCD photopolymer 3D printing uses liquid crystal display (LCD) photolithography technology. The resin is cured gradually from a liquid state by being illuminated by LED light emitted from the LCD screen. During the process, the LCD panel blocks some of the light, allowing only certain areas to be exposed to the photosensitive resin. Layers are repeatedly cured, and finally, the finished product is created. ( Click here to see the corresponding equipment )

SLA (Stereolithography) 3D printing technology uses focused ultraviolet (UV) light to cure resin, which is sensitive to light. It's a photolithography method, like drawing a solid with light. After a single layer is formed, the work platform descends one layer and is re-immersed in the resin tank. This process is repeated until the part is complete. ( Click here to see the corresponding equipment )

• DLP projection lighting (Digital Light Processing)

DLP uses the flickering beam of a digital projection screen to cure the photosensitive resin. Each layer of the digitally projected image is composed of square pixels; the finer the pixel particles, the better the print quality! The projection beam can be projected perfectly and tightly onto the printing platform, achieving a faster molding speed. (Please contact us if you need information about the corresponding equipment.)

| Printing speed | LCD ≈ DLP > SLA |

| cost | SLA > DLP > LCD |

| Surface precision | It varies depending on the size of the laser dots or the particles on the panel. |

Photopolymer 3D printing is suitable for producing complex-shaped parts and models. The finished product has a smooth surface with very few material stacking patterns, making it ideal for producing small to medium-sized modular parts, assembled objects, and models. It has been widely used in engineering industries such as dentistry and jewelry. The finished product can present high-precision details, and there is a variety of resin materials to choose from, ranging from casting- specific , high-temperature resistant , high-toughness , and transparent . Colors can also be selected according to requirements.

The principles of SLA, DLP, and LCD photopolymer 3D printing are very similar. Which one do you prefer? Feel free to share with us! SanDiMa offers more than just 3D printing . Contact us now to learn more about application examples and detailed equipment information for photopolymer 3D printers .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

https://www.instagram.com/3dmart/