Bambu Lab breaks through the framework of traditional 3D printers, launching H2D , which integrates 3D printing, laser engraving, drawing, and cutting functions.

This product not only continues Bambu Lab's consistent advantages in ease of use and technological innovation, but also boldly innovates in functional modularity, aiming to meet the diverse needs of advanced users and makers for cross-media processing.

This time, we'll be unboxing the 40W laser version of H2D!

👉Click here to see our previous unboxing of the H2D AMS COMBO

The H2D 40W Laser Kit includes all the available tools for H2D.

In addition to 3D printing capabilities, this kit also includes a cutting module with a pen holder and a 40W diode laser module.

In addition, a lower-power 10W laser is also available.

Create more possibilities with laser and cutting modules.

For those unfamiliar with the uses of such tools, imagine a two-dimensional world.

Flat, stackable designs and cuts, or components that can be applied to other objects to add effect and tactile feel.

Decals, labels, frames, inlays... sometimes the results of using multicolor 3D printing technology for these things may not be very good.

The materials you choose depend on the tools you use.

H2D's cutting module is a shallow drag blade that can cleanly and efficiently cut thin materials such as paper, cards, vinyl, and certain fabrics.

Laser modules are suitable for cutting or carving wood, acrylic, and similar materials that are more than a millimeter thick.

.jpg)

The laser or cutting module is mounted on the front end of the H2D printhead and locked in place by a lever based on friction.

This means that H2D is superior to many brands of multi-tools because it can keep the base tool head (3D printing element) fixed.

Switching between functions only requires attaching an external print head, rather than removing and replacing it, which is more efficient.

40W laser module

A 40W laser can cut thicknesses of several millimeters in a single pass.

Therefore, an air-assisted pipe must be connected to help H2D blow away debris during the cutting process.

The air pump hose connects to the connector between the two guide wire connectors at the rear of the H2D chamber. The safety screw needs to be removed to make the air pump work.

H2D's laser construction plates can be used to place laser-cut materials, and the sparse strips can be freely adjusted in spacing, making them suitable for materials that require various contact points.

As we would expect from a high-end Bambu Lab system, it boasts a wealth of automation and self-testing capabilities.

H2D uses multiple cameras to read barcodes on the printing platform to ensure that the software recognizes the content on the platform and is compatible with your desired goals.

Laser modules can easily cut various materials such as leather, cork, wood, and paper in a short time.

The 40W laser module can also leave marks on certain metals.

Whether it's 10W or 40W, both of Bambu Lab's laser modules are blue diode lasers, which means they can sculpt and cut a wider variety of materials.

Bambu Suite

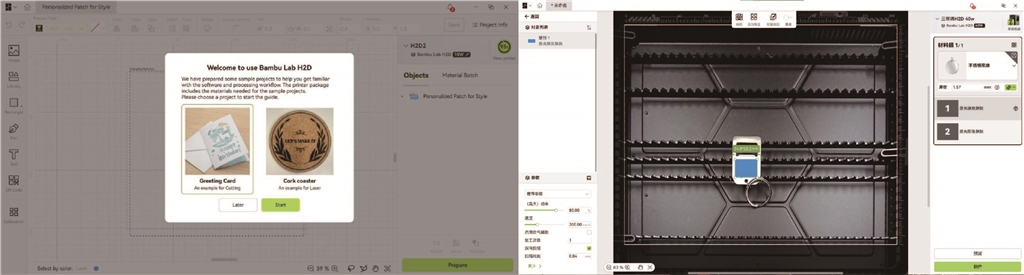

Bambu Suite can create and manage all jobs that use H2D non-3D printing capabilities, including laser and cutting, as well as pen holder drawing.

You can combine these functions into a single job, or even integrate them with your regular 2D printer to achieve "print first, cut later" functionality.

Unlike 3D printing, which requires loading a model, configuring settings, and then slicing (actually a preparation, preview, and printing process), 3D printing requires loading a model, configuring settings, and then slicing.

In contrast, Bambu Suite provides a creative space and tools for creating from scratch.

These tools include basic primitive shapes, text (with a deep font library), an image library containing emojis and other common icons, and a pen tool for point-to-point drawing and curves.

In addition, it provides a QR code generation tool, as well as the function of adding offset borders similar to stickers to artwork.

After the creation phase is over, you will work in the preparation area.

Here, you can access the intelligent features of Bambu Suite, such as batch processing and automatic alignment.

H2D's camera array allows you to precisely view the work area and place design drafts in the frame, aligning them correctly with the material.

Security

Bambu Lab has gone to great lengths to install a series of fire sensors in a fully enclosed facility and has built in a powerful exhaust system that can quickly remove smoke from the room, thus ensuring user safety.

H2D powerfully exhausts air from the cabin through a three-layer filter, then discharges the purified air through the exhaust pipe and guides it to an open window or air purifier for optimal effect.

Each H2D hose and clamp comes with several meters of tubing, from the H2D itself to the exhaust fan and then to the window, giving you flexibility when placing items.

Another difference between H2D laser and 3D printing workflows is that all cutting operations require you to be present at the machine.

You must press the button to confirm the job; both the machine and the software will remind you not to leave the machine.

The H2D full laser version comes standard with a red, pressable emergency stop button.

If any problems occur, you can stop the machine from operating immediately.

Once the laser job is complete, as long as H2D knows the material being sculpted or cut, a countdown timer will appear, requiring you to wait a certain period before removing the material to allow the smoke to dissipate fully.

H2D's laser treatment is very clean, and the machine is also equipped with a maintenance tracker that records each job. Eventually, H2D will remind you when it needs cleaning.

Is H2D worth it as a multi-functional machine?

The longer you work with these types of tools and machines, the more complementary materials and processes you'll discover.

Pure 3D printing can create fantastic items, but cork mats, foam bases, and felt pads are simple cutting operations that can significantly enhance the tactile feel of 3D printing.

Therefore, from this perspective, H2D is a very practical machine.

If your attraction to H2D lies in its multi-material handling capabilities, then H2D is the ideal choice for you.

Its basic configuration is an excellent dual extruder, which uses two nozzles to achieve efficient and fast multi-color and multi-material printing.

Furthermore, by adding multiple Bambu Lab AMS devices, you can maximize this functionality, thereby increasing the number of consumables you can use in a task.

While some of the features of H2D can be found in other systems, no other product can currently match H2D in terms of versatility.

For more information on the specifications of Bambu Lab H2D, please visit our product page !

You are also welcome to contact us for more information!

H2D Installation Instructions

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | T hreads

References