[3D Printing] Unboxing the Bambu Lab H2C AMS Combo!

SanDiMa is an officially authorized distributor of Bambu Lab. You are welcome to visit our store to see the H2C machine in person!The H2C is the latest iteration of the Topzhu H series 3D printers. The previous H2D in this series caused a sensation.

The H2D is a large-size, dual-printer, fully enclosed printer equipped with a tool change module and capable of processing a variety of different materials.

The subsequent H2S simplified operation with a single printhead design, but still achieved large-format printing at a lower cost and with a larger print size.

H2C is now expanding the ecosystem by offering multiple nozzle replacement tool heads.

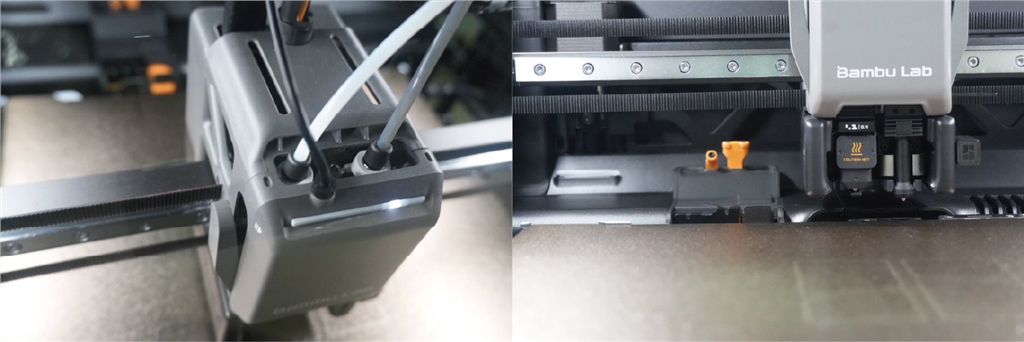

It basically uses the same hardware as other H-series printers, with the biggest difference being the addition of a module on the right side of the machine.

Opening the module reveals six additional nozzles that can be frequently replaced in the tool head to accommodate different consumables without requiring as much consumable cleaning as with the previous system.

H2C is fascinating from the start. The entire setup process takes about 20 minutes, including loading each printhead into the magnetic holder, installing the AMS and the second roll of supplies, but it is still very simple.

As always, Bambu Lab provides detailed instructions to guide users.

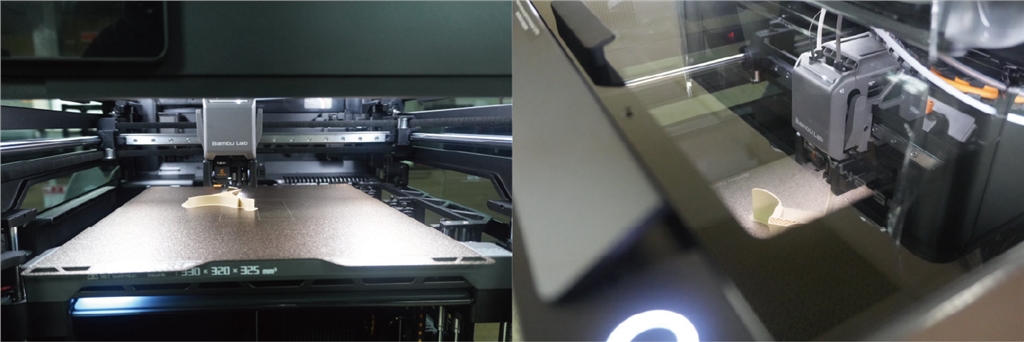

Unboxing H2C

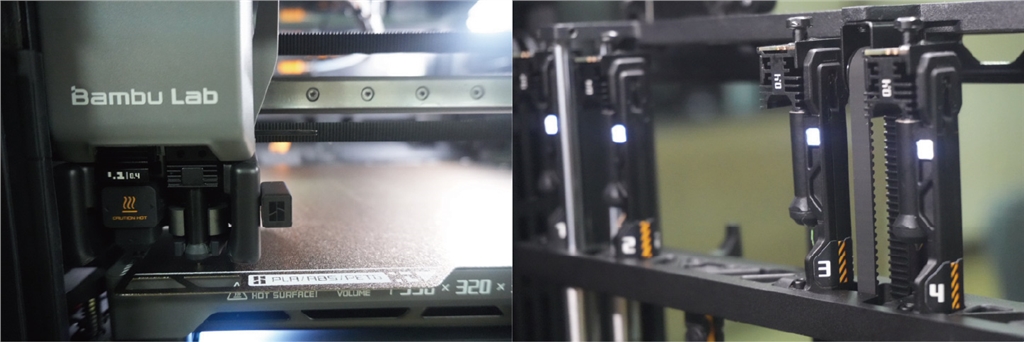

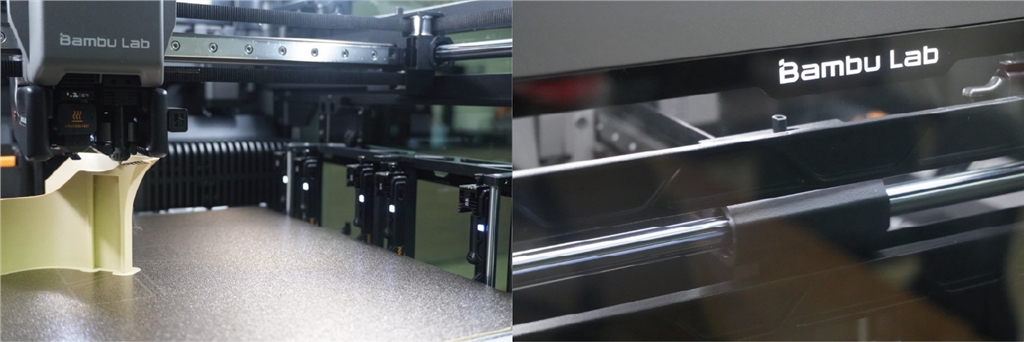

The H2C looks almost identical to the H2D and H2S. The real change is in the tool head.

It is equipped with a common fixed nozzle on the left side, which supplies material through an external feed port (normally, a consumable is fixed on the spool bracket on the left side).

The right side is equipped with a nozzle for feeding via AMS.

This nozzle can access five other nozzles via the Vortek system located on the right side of the machine.

This new system is what excites everyone because it is so different from the multi-tool head designs we have seen from other brands before.

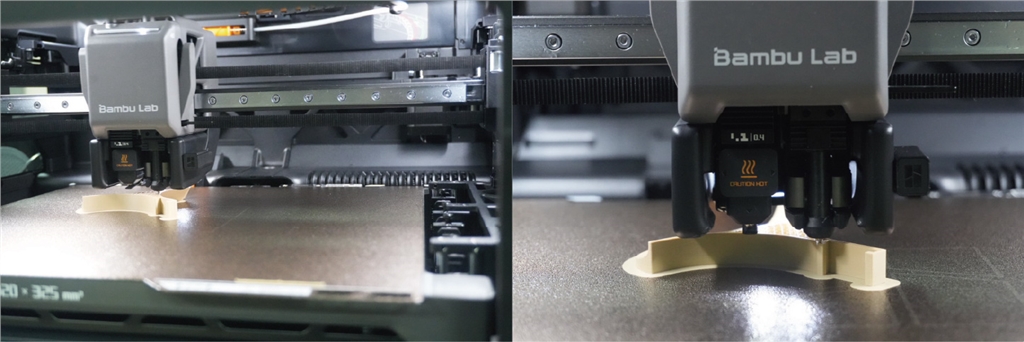

Essentially, H2C doesn't use a printhead for each type of filament, but rather a nozzle for each consumable.

The nozzle on the right is used to load and unload wires , which are then loaded or removed through the nozzle.

After loading, there will still be a back-pull and chip removal process, but since each consumable has its own nozzle, the amount of chip removal is greatly reduced.

This system also means that you can use some nozzles for commonly used wires and others for less commonly used wires .

For example, if you want to print a 12-color pattern, you can connect 3 AMS nozzles to the right tool head, assign the primary color to the left nozzle, assign the second, third, and fourth most frequently used filaments to the first three nozzles of the Vortek system, and then assign the remaining eight colors to the remaining three nozzles of the Vortek system.

While these nozzles still require cleaning like H2D nozzles, cleaning is limited to less frequently used filaments , which helps speed up the overall printing process.

The original H2C package contains four Vortek 0.4mm induction hot ends, one 0.2mm hot end, and one 0.6mm hot end.

Alternatively, you can choose to equip yourself with an AMS2 Pro and a 40W or 20W laser, or purchase an additional hot end.

The H2C hot connector looks very similar to the hot connector used on the H2D.

The only difference is that it is now equipped with the Vortek Automatic Hot End Replacement System, and each hot end is secured in place by a brand new mechanism.

This allows the machine to automatically and quickly change the hot end without requiring manual operation.

The Vortek system is essentially a clever hot-end mounting system, installed on the right side of the machine.

When you perform the initial configuration, the system will ask you to install each hot end and show you the process of raising and lowering each nozzle on the bracket.

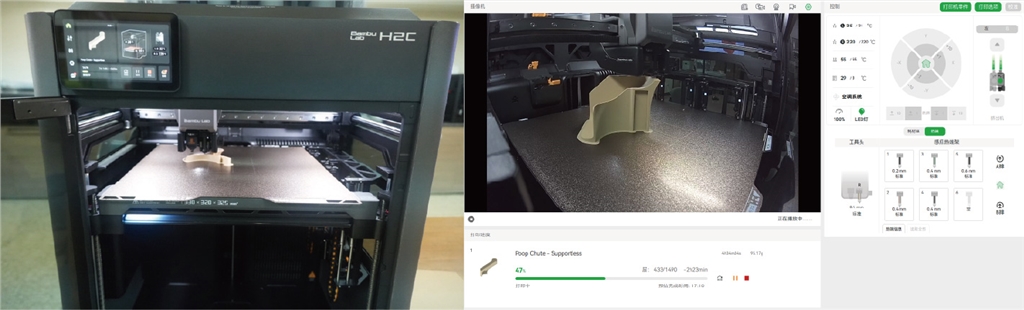

The H2C machine itself is equipped with a 5-inch color touchscreen, which will be very convenient to operate if you have used Bambu Lab's printers before.

Even if it's your first time using it, the user interface is extremely simple and easy to use, and you'll get the hang of it quickly.

H2C's design and workmanship once again demonstrate its superior quality, and it is designed specifically for the professional market.

The entire casing is made of glass and metal, showcasing a high-end feel.

Because the entire device is completely sealed, it has a temperature-controlled, enclosed space with automatic ventilation.

This allows you to print a variety of materials in optimal conditions, including PLA without opening the top cover or hatch.

Install H2C

Installing the H2C takes approximately 20 minutes. In practice, once all the internal packaging is removed, all that's really needed during installation is to insert the AMS and install the new nozzle used on the right side of the tool head.

The AMS connection is the same as other Tuozhu models: simply insert it into the back, connect it to the inlet with a tube, and then connect the device and AMS Pro with a data cable.

External consumables are connected to the left nozzle via a spool bracket located at the rear of the device, which snaps into place and extends from the left side.

If you wish to use the AMS HT external drying box, you can place it next to the machine and use a longer tube to deliver the consumables. Everything is very convenient and simple.

The installation of H2C's magnetic nozzles is very simple.

The nozzle is packaged separately and can be installed with a simple press.

The nozzle has two holes inside, which align with two pins on each nozzle seat, so that each nozzle can be securely mounted on the Vortek system.

After completing the above steps, simply run the setup program. Once calibration is complete, you can open Bambu Studio. Load the model and synchronize consumables and nozzles.

If you've used a Bambu Lab printer before, you'll know that it uses RFID tags on the cable reel to automatically identify loaded consumables, thus enabling cable synchronization.

The process is exactly the same. Simply sync your supplies, and they will appear automatically; no manual input is required. If you are using third-party cables , you can manually input them through the settings options.

The nozzles work on almost the same principle; they will automatically recognize each other once they are synchronized.

The system will prompt you to synchronize, and then perform a quick calibration procedure. After that, you can basically start using it.

Loading print files is the same as any other Bambu.

You can quickly send 3D print files remotely to the machine, which will then display a clear, real-time image, allowing you to monitor the printing progress and ensure everything runs smoothly.

The best thing about the H2C is its cable usage. Compared to the other two models in the H series, it saves a considerable amount of consumables. The cable waste of the H2C is less than half that of the H2D and almost one-third that of the H2S.

Therefore, if you run a business, using H2C can significantly reduce your consumable costs.

High-efficiency and cost-saving multi-color and multi-material applications

Vortek's hot-end system is truly innovative. Compared to H2D or H2S, it allows for hot-end replacement with almost no cleaning required.

You can use a wide variety of materials, so whether you're a high-end hobbyist, a small business, or a printing plant, it can handle everything from standard PLA to nylon, carbon fiber fillers, and virtually any other specialty material you can think of.

This print chamber can be heated up to 65°C, and with a 350°C hot end, it provides you with great flexibility when printing.

In addition, the AMS system not only supports the seven different consumables currently available out of the box, but can also support up to 24 consumables by adding more AMS units.

Many people's vision for this machine, and their biggest concern, is: can it reduce waste of consumables?

The answer is yes, although it cannot be completely eliminated, it is enough to have a significant impact.

The H2C is a truly innovative and outstanding machine. It takes a different approach from most manufacturers, using multiple nozzles instead of a tool head.

If you've already used the Bambu ecosystem, then this printer is perfect for you.

It is ideal for studios, engineers, prototyping professionals, or anyone who needs a high-quality cable that can print beautiful work and is compatible with a variety of different materials.

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | T hreads